Nov . 18, 2024 23:37 Back to list

rubber seals for doors and windows manufacturers

Rubber Seals for Doors and Windows A Comprehensive Overview

Rubber seals for doors and windows play a crucial role in enhancing the energy efficiency, comfort, and security of homes and buildings. Among the various components that contribute to the overall performance of doors and windows, rubber seals are often overlooked, yet they are essential in addressing several key issues.

Importance of Rubber Seals

Rubber seals serve multiple purposes; they act as barriers against water, dust, and air infiltration, ensuring that the indoor environment remains comfortable and protected from external elements. In addition, they help in reducing noise pollution and protect against pests, which can be particularly beneficial for homes located in urban areas or near busy roads.

A well-sealed door or window can significantly help in regulating indoor temperatures, which in turn lowers energy consumption and costs. The HVAC system does not have to work as hard to maintain the desired temperature, ultimately extending its lifespan and reducing maintenance costs.

Types of Rubber Seals

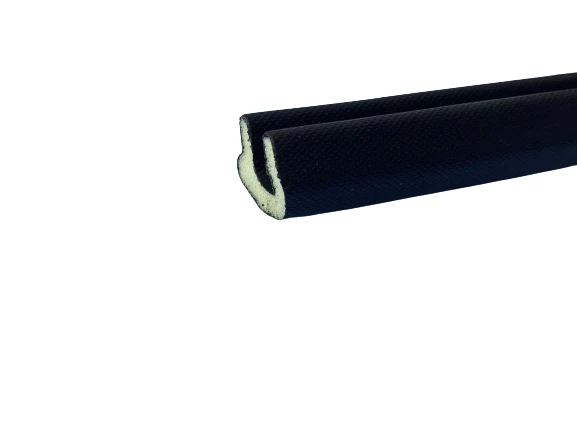

Manufacturers offer a range of rubber seals suitable for various applications in doors and windows. Some common types include

1. EPDM Seals Ethylene Propylene Diene Monomer (EPDM) rubber seals are known for their excellent weather resistance, making them ideal for exterior applications. They can withstand extreme temperatures and UV exposure without degrading.

2. Silicone Seals Silicone rubber is highly flexible and provides a superior seal against water and air. Its elasticity allows it to expand and contract, making it suitable for high-performance applications.

4. Butyl Seals Known for their adhesive properties, butyl rubber seals are often used for metal doors and windows as they provide an airtight seal and are resistant to moisture.

rubber seals for doors and windows manufacturers

Manufacturing Process

The manufacturing of rubber seals typically involves several stages, including compounding, molding, and curing. During the compounding phase, raw rubber is mixed with various additives to enhance its properties, such as durability, flexibility, and resistance to environmental factors.

Once the rubber is compounded, it is molded into the desired shape using hydraulic presses or extrusion methods. After molding, the rubber seals undergo a curing process, often referred to as vulcanization, which involves heating the rubber to create cross-links between the polymer chains. This process enhances the strength and elasticity of the seals.

Quality control is a vital aspect of the manufacturing process. Manufacturers ensure that the seals meet specific industry standards and customer requirements. Factors such as tensile strength, elongation at break, and resistance to aging and weathering are carefully tested.

Choosing the Right Manufacturer

When selecting a manufacturer for rubber seals for doors and windows, it is essential to consider several factors. Look for a company with a proven track record in the industry, offering a variety of products that cater to specific needs. Certifications and compliance with industry standards can indicate the quality of the products.

Customer reviews and testimonials also provide valuable insight into a manufacturer's reliability and product performance. Furthermore, manufacturers that offer customization options can help in developing seals that fit unique door and window configurations.

Conclusion

Rubber seals for doors and windows are not merely functional components; they are vital to creating a comfortable, energy-efficient, and secure living environment. With advancements in manufacturing techniques and materials, today’s rubber seals offer enhanced performance and longevity. By partnering with reputable manufacturers, homeowners and builders can ensure that they are investing in high-quality seals that will stand the test of time.

In summary, understanding the importance of rubber seals, their types, manufacturing processes, and choosing the right manufacturer can significantly impact the comfort and efficiency of homes and commercial buildings. Quality rubber seals represent a small investment that yields considerable returns in energy savings and enhanced living conditions.