Dec . 06, 2024 10:42 Back to list

Rubber Sheeting Roll for Versatile Applications in Manufacturing and Construction

The Importance of Rubber Sheeting Rolls in Various Industries

In contemporary manufacturing and industrial applications, rubber sheeting rolls have emerged as indispensable materials. This versatile product is employed in a wide array of industries due to its unique properties, including elasticity, resilience, and durability. From automotive to construction, rubber sheeting rolls play a critical role in ensuring efficiency, safety, and functionality.

Composition and Types of Rubber Sheeting Rolls

Rubber sheeting is made from various types of rubber, depending on the intended application. Common materials include natural rubber, neoprene, EPDM (ethylene propylene diene monomer), and nitrile rubber. Each type of rubber offers distinct properties tailored to meet specific needs

- Natural Rubber Known for its excellent elasticity and tensile strength, natural rubber is primarily used in applications requiring high stretchability.

- Nitrile Rubber This synthetic rubber boasts outstanding resistance to oil and fuels, making it ideal for automotive and industrial applications.

- EPDM Renowned for its weather resistance, EPDM is commonly used in roofing and outdoor applications where exposure to UV, ozone, and harsh weather conditions is prevalent.

- Neoprene With its balance of flexibility and strength, neoprene is often utilized in items that require buoyancy, fire resistance, and weatherproofing, such as wetsuits and protective gear.

Applications Across Industries

1. Construction In the construction sector, rubber sheeting rolls are used for waterproofing and insulation. They are often installed on roofs and foundations to prevent water ingress. The elasticity and durability of rubber create a reliable barrier against leaks and environmental damage, enhancing the longevity of structures.

2. Automotive In the automotive industry, rubber sheeting serves multiple purposes, including gaskets, seals, and mats. Nitrile rubber, in particular, is prevalent in manufacturing parts that need to resist oil, chemicals, and extreme temperatures. Rubber rolls are also used for sound dampening inside vehicles, contributing to a quieter and more comfortable ride.

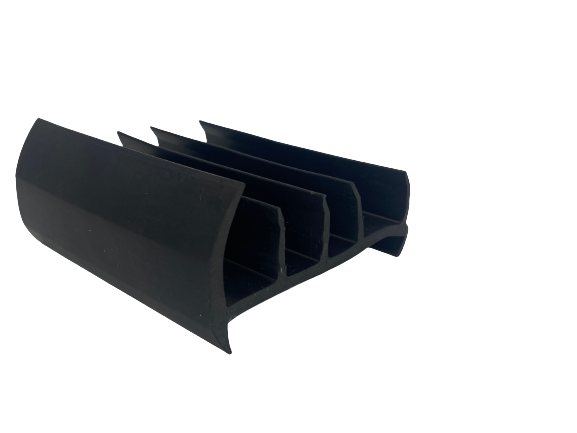

rubber sheeting roll

3. Manufacturing In manufacturing plants, rubber sheeting rolls are integrated into machinery as protective mats and floor coverings. They provide traction, reduce noise, and minimize wear on equipment. Their resilience against wear and tear makes them suitable for high-traffic areas where heavy machinery operates continuously.

4. Sports and Recreation The sports industry benefits significantly from rubber sheeting rolls, especially in the production of gym mats and flooring systems. The shock-absorbing properties of rubber help prevent injuries during athletic activities, providing a safe surface for both training and competitions.

5. Healthcare In healthcare settings, rubber sheeting is often used for flooring in hospitals and clinics. Its easy-to-clean surface and slip-resistant qualities make it a practical choice for sterile environments where safety and hygiene are paramount.

Benefits of Rubber Sheeting Rolls

The advantages of using rubber sheeting rolls extend beyond just practicality. Their lightweight nature and ease of handling contribute to reduced labor costs during installation and maintenance. Moreover, rubber is inherently resistant to many chemicals and environmental conditions, ensuring that products made from rubber sheeting can maintain their integrity over time.

Additionally, rubber sheeting rolls are available in various thicknesses and widths, allowing manufacturers to customize their applications according to specific requirements. This adaptability provides significant flexibility for industries, catering to diverse design and engineering needs.

Sustainability and Environmental Considerations

As industries worldwide move toward sustainable practices, the rubber industry is making strides to incorporate recycled materials and eco-friendly production processes. Many manufacturers are now offering rubber sheeting rolls made from recycled rubber, thereby reducing waste and promoting environmental responsibility. This shift not only helps mitigate ecological impact but also offers businesses cost-effective solutions.

Conclusion

Rubber sheeting rolls are a cornerstone of modern industrial practices, woven into the fabric of multiple sectors. Their versatility, combined with the evolution of sustainable production methods, ensures that rubber sheeting will continue to be a vital resource for innovation and efficiency. Moving forward, industries will undoubtedly seek to leverage the unique properties of rubber sheeting, driving further advancements and applications that enhance both functionality and sustainability in a rapidly changing world.

Next:

Prev: