Jul . 25, 2024 22:39 Back to list

Sealant Strips for Gaps in Solar Panels to Enhance Efficiency and Performance Solutions

Sealing Strips for Gaps in Photovoltaic Solar Panels An Essential Component for Efficiency

In the ever-evolving domain of renewable energy, photovoltaic (PV) solar panels stand out as a leading technology for harnessing solar power. As solar energy becomes more integral to global energy strategies, ensuring the efficiency and longevity of solar panels is paramount. One often-overlooked component that plays a crucial role in maintaining the efficiency of these panels is the sealing strip for gaps.

Understanding the Role of Sealing Strips

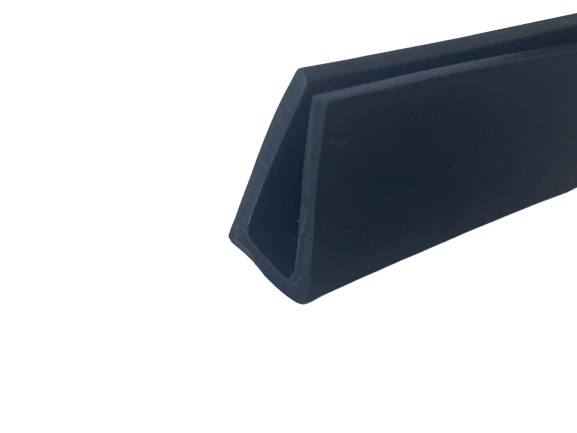

Sealing strips are specially designed materials used to fill the gaps between solar panels and their mounting systems. These gaps, while seemingly insignificant, can lead to various issues, including reduced energy efficiency, moisture accumulation, and potential damage to the panels themselves. By using sealing strips, manufacturers can create robust, watertight installations that not only enhance the performance of the panels but also prolong their lifespan.

One of the main functions of sealing strips is to prevent water from infiltrating the spaces between solar panels. Moisture can lead to several problems, including corrosion of electrical components and the degradation of solar cells. By ensuring that these gaps are properly sealed, sealing strips help mitigate the risks associated with water intrusion, thereby maintaining optimal performance levels throughout the solar panel's operational life.

Benefits of Using Sealing Strips

1. Energy Efficiency Gaps can disrupt the airflow and create thermal bridges, leading to inefficiencies in energy production. Sealing strips maintain consistent temperature management, which can enhance energy output, ensuring that solar panels function at their highest capacity.

2. Durability Solar panels are exposed to various environmental conditions, including rain, wind, and extreme temperatures. Sealing strips provide an extra layer of protection against such elements, reducing wear and tear on the panels and extending their operational life.

sealing strip for gaps in photovoltaic solar panels products

3. Cost-Effectiveness Although the initial investment in quality sealing strips may be higher, the long-term savings due to increased efficiency and reduced maintenance costs make them a wise investment. By preventing moisture damage and enhancing overall system reliability, sealing strips can lead to significant savings over time.

4. Enhanced Aesthetics In addition to their functional benefits, sealing strips can improve the overall appearance of solar installations. They provide a clean finish, creating a seamless transition between the panel and its mounting system.

Selection of the Right Sealing Strip

When selecting sealing strips for PV installations, several factors should be considered, including material composition, weather resistance, and compatibility with panel designs. Common materials used for sealing strips include silicone, EPDM rubber, and foam. Each material has unique properties that cater to specific environmental conditions and installation requirements.

For example, silicone sealing strips offer excellent temperature stability and UV resistance, making them ideal for areas with extreme weather fluctuations. On the other hand, EPDM rubber is known for its durability and ability to withstand prolonged exposure to moisture, making it a suitable choice for humid climates.

Conclusion

As the global focus on renewable energy continues to grow, the importance of every component in a solar installation—including sealing strips—cannot be overstated. By effectively sealing the gaps in photovoltaic solar panels, these strips play a pivotal role in enhancing efficiency, durability, and overall performance. With the right selection and application of sealing strips, solar installations can achieve their full potential, contributing to a sustainable energy future. Investing in quality sealing solutions is not just an option but a necessity for maximizing the benefits of solar energy systems.