Oct . 14, 2024 01:49 Back to list

sealing strip for gaps in photovoltaic solar panels supplier

Sealing Strips for Gaps in Photovoltaic Solar Panels A Comprehensive Overview

The increasing adoption of photovoltaic (PV) solar panels as a renewable energy source has led to a growing need for effective sealing solutions to address the gaps and joints in these installations. One critical component that ensures the longevity and efficiency of solar panels is the sealing strip. This article explores the importance of sealing strips, their functionality, and how to select a reliable supplier.

The Importance of Sealing Strips

Sealing strips serve multiple purposes in photovoltaic solar panel installations. Primarily, they play a crucial role in preventing moisture ingress, which can lead to corrosion and malfunction of the panels over time. Water intrusion can compromise the electrical components and reduce the overall energy output, emphasizing the need for robust sealing solutions.

Moreover, sealing strips assist in maintaining the structural integrity of solar panels. They help absorb thermal expansion and contraction caused by varying environmental conditions, thereby reducing the risk of cracking and delamination. By ensuring that the panels are well-sealed, you enhance their performance and longevity, resulting in a better return on investment for solar energy systems.

Types of Sealing Strips

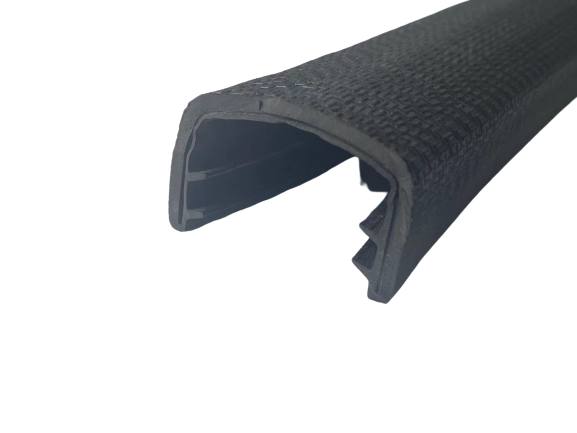

There are various materials used in the manufacturing of sealing strips, including silicone, EPDM (Ethylene Propylene Diene Monomer), and PVC (Polyvinyl Chloride). Each material presents unique advantages

1. Silicone Sealing Strips These are known for their excellent flexibility and durability. Suitable for extreme temperatures, silicone strips can withstand the intense sunlight and varying weather conditions that solar panels are often exposed to.

2. EPDM Strips Renowned for their resistance to UV radiation and weathering, EPDM strips are an ideal choice for outdoor installations. They provide a reliable seal and are often used in installations that experience significant thermal fluctuations.

sealing strip for gaps in photovoltaic solar panels supplier

3. PVC Strips While more affordable, PVC strips may not offer the same level of durability as silicone or EPDM. They can be suitable for specific applications but may require more frequent replacements.

Selecting a Reliable Supplier

When looking for a supplier of sealing strips for photovoltaic solar panels, several factors should be considered to ensure that you choose a reliable partner

- Quality Assurance Look for suppliers who adhere to industry standards and have a track record of providing high-quality products. Certifications and customer reviews can be helpful indicators of reliability.

- Expertise in Solar Industry Suppliers with experience in the solar energy sector will better understand the specific challenges presented by solar panel installations and can offer tailored solutions.

- Customization Options Every installation may have unique requirements. A good supplier should offer customizable sealing solutions that meet your project specifications.

- After-Sales Support Consider the level of customer service and support a supplier offers post-purchase. This aspect can be crucial in addressing any issues that may arise during installation or in the product's lifecycle.

Conclusion

In conclusion, sealing strips are essential components for the effective functioning and longevity of photovoltaic solar panels. Their ability to prevent moisture intrusion, manage thermal expansion, and maintain structural integrity makes them indispensable in solar energy installations. By selecting a reputable supplier, you can ensure that your solar panels are equipped with high-quality sealing solutions, paving the way for sustainable and efficient energy production. Investing time in sourcing the right sealing strips can ultimately lead to enhanced performance and reliability of your photovoltaic systems.