Nov . 14, 2024 08:19 Back to list

self adhesive door and window sealing strip factories

The Rise of Self-Adhesive Door and Window Sealing Strip Factories

In recent years, the demand for self-adhesive door and window sealing strips has surged, driven by a growing awareness of energy efficiency and the need for better insulation in buildings. These sealing strips play a crucial role in minimizing air leaks and improving the overall energy efficiency of residential and commercial spaces. As a result, factories dedicated to the production of these essential products have emerged as a vital sector in the manufacturing industry.

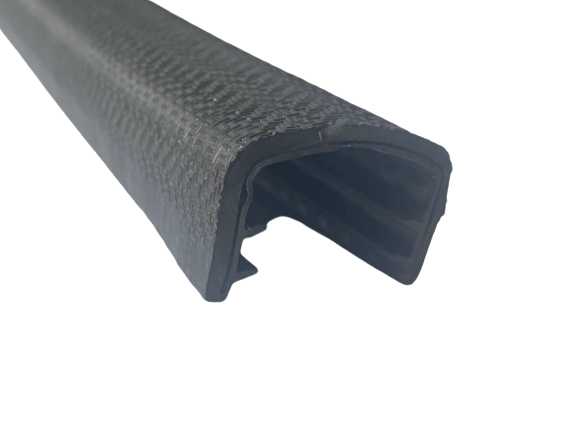

Self-adhesive sealing strips are typically made from a variety of materials, including rubber, silicone, and foam, which provide effective seals for doors and windows. The adhesive backing allows for easy installation, making these strips an attractive option for homeowners and builders alike. They can be applied to various surfaces without the need for additional tools or adhesives, ensuring a user-friendly experience. The convenience and effectiveness of self-adhesive sealing strips have made them a popular choice for DIY enthusiasts and professional contractors.

The rise of self-adhesive door and window sealing strip factories can be attributed to several key factors. First, the global movement toward sustainable building practices has increased the need for energy-efficient solutions. Governments and organizations are implementing stricter building codes and regulations that focus on minimizing energy consumption. This trend has led to a greater emphasis on sealing techniques, driving demand for high-quality sealing strips.

self adhesive door and window sealing strip factories

Moreover, advancements in manufacturing technology have enabled factory owners to produce high-performance sealing products at competitive prices. Modern production techniques allow for the mass production of sealing strips, reducing costs and making them more accessible to consumers. This has spurred innovation within the industry, leading to the development of new materials and designs that enhance the efficacy and durability of sealing strips.

In addition to increased production capabilities, self-adhesive sealing strip factories are also adopting sustainable practices to minimize their environmental impact. Many manufacturers are now focusing on using eco-friendly materials and producing their products using energy-efficient processes. This commitment to sustainability not only meets rising consumer expectations but also aligns with global initiatives aimed at reducing carbon footprints.

The competitive landscape of this industry is vibrant and diverse, with numerous factories emerging worldwide. Some focus on producing specialized sealing strips designed for specific applications, such as noise reduction or weatherproofing, while others cater to a broader market. As the market grows, companies are finding new ways to differentiate themselves, such as offering customizable solutions or exceptional customer service.

In conclusion, the rise of self-adhesive door and window sealing strip factories is a testament to the increasing awareness of energy efficiency and sustainable living. With a focus on innovation, quality, and eco-friendliness, these manufacturers are not only meeting the needs of today’s consumers but are also shaping the future of the sealing industry. As the demand for effective sealing solutions continues to grow, these factories will undoubtedly play a crucial role in promoting energy conservation and enhancing the comfort of living and working spaces around the globe.

Next:

Prev: