Dec . 03, 2024 21:51 Back to list

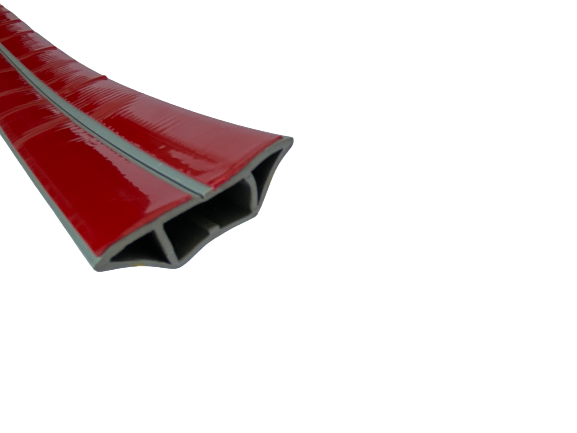

sheet epdm rubber

The Versatility and Applications of EPDM Rubber

Ethylene Propylene Diene Monomer (EPDM) rubber is a synthetic elastomer known for its exceptional resistance to heat, UV radiation, and weathering. Commonly used in various industries, EPDM offers a unique combination of properties that make it suitable for an expansive range of applications.

Composition and Properties

EPDM is a copolymer derived from ethylene, propylene, and a diene monomer. This unique combination of ingredients gives EPDM its elasticity, strength, and durability. Unlike natural rubber, EPDM is not susceptible to ozone degradation, which makes it a fantastic option for outdoor applications. Furthermore, it has a low-temperature flexibility that allows it to maintain its performance in extreme conditions.

One of the standout features of EPDM is its resistance to oxidizing agents, which include heat, chemicals, and various environmental factors. This resistance allows EPDM components to last longer, reducing the need for frequent replacements. Additionally, EPDM has excellent aging properties, ensuring that products made from this rubber can withstand the test of time.

Applications of EPDM Rubber

EPDM rubber's versatile characteristics make it suitable for numerous applications

1. Automotive Industry EPDM is predominantly used for manufacturing weather stripping and seals in vehicles. Its excellent resistance to UV rays and extreme temperatures makes it ideal for this purpose. Furthermore, EPDM is used in hoses, gaskets, and other components that require durability and longevity.

2. Construction Sector In the construction industry, EPDM is widely utilized as a roofing material. EPDM roofing systems provide excellent waterproofing and insulation, making them a popular choice for flat roofs. The material is easy to install and provides long-lasting protection against leaks and weather conditions.

sheet epdm rubber

3. Electrical Insulation EPDM rubber is an excellent insulator, making it suitable for electrical applications. It is often used in the manufacturing of wires and cables, ensuring safety and reliability in electrical systems.

4. Automotive and Industrial Hoses Due to its flexibility and resilience, EPDM is frequently used to manufacture hoses for vehicles and industrial applications. These hoses can withstand high temperatures and pressures, ensuring reliable fluid transport in various settings.

5. Consumer Products EPDM is also found in numerous consumer goods, such as seals for appliances, playground surfaces, and automotive parts. Its ability to withstand irregular usage and diverse conditions makes it a reliable choice for manufacturers.

Advantages of EPDM Rubber

The benefits of using EPDM rubber are manifold. Its resistance to harsh weather conditions extends the lifespan of products, leading to cost savings for manufacturers and consumers alike. Moreover, EPDM's versatility in formulation allows manufacturers to tailor its properties to meet specific needs, enhancing performance across various applications.

In addition, EPDM is an environmentally friendly option compared to other synthetic rubbers. It can be produced without petroleum feedstocks, making it a more sustainable choice for manufacturers aiming to reduce their carbon footprint.

Conclusion

In summary, EPDM rubber stands out as a versatile material with diverse applications across multiple industries. Its unique properties, coupled with its longevity and resistance to environmental factors, make it an indispensable material in automotive, construction, electrical insulation, and consumer product sectors. As industries continue to seek durable and reliable materials, EPDM rubber will undoubtedly maintain its position as a favored choice for manufacturers and engineers alike.