Dec . 11, 2024 10:29 Back to list

Effective Solutions for Shipping with Quality Rubber Fenders in Marine Applications

The Role of Ship Rubber Fenders in Maritime Operations

In maritime operations, the importance of ship safety cannot be overstated. One of the critical components in ensuring the protection of vessels and docking facilities is the use of rubber fenders. These specialized marine cushioning devices play a vital role in reducing the impact of ships colliding with docks, berths, and other vessels, thereby preventing damage and ensuring safe operations.

Understanding Ship Rubber Fenders

Ship rubber fenders are specifically designed to absorb the kinetic energy generated during the contact between vessels and docking structures. Made from durable materials, such as synthetic rubber, fenders are engineered to withstand harsh marine conditions while providing optimal cushioning. Their primary function is to dissipate the energy from vessel impacts, which can otherwise lead to considerable damage to both the ships and the berthing structures.

Types of Rubber Fenders

There are several types of rubber fenders used in the maritime industry, each designed for specific applications and vessel sizes

. Some of the most common types include1. Extruded Fenders These fenders feature a simple cylindrical design and are often used for smaller vessels or lighter applications. Their shape allows for easy installation and adaptability to various docking scenarios.

2. Doughnut Fenders Shaped like large doughnuts, these fenders provide robust cushioning and are ideal for both small and large vessels. They are particularly effective in absorbing impacts and are commonly used in boathouses and marinas.

3. Cell Fenders These are structured with individual cells or compartments and are designed for high-energy impacts. Their unique design allows them to absorb greater amounts of kinetic energy, making them suitable for larger cargo ships and container vessels.

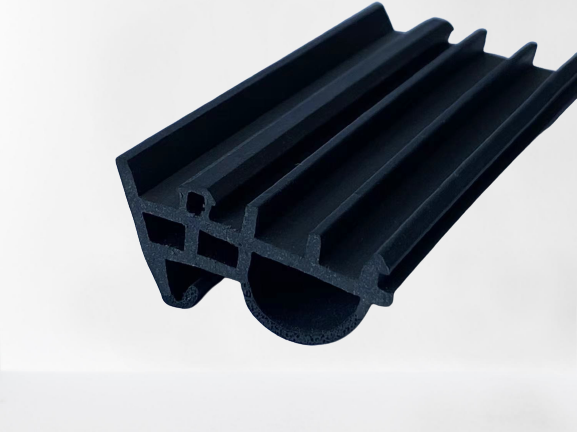

ship rubber fender

4. Corner Fenders Specifically designed for use on the corners of docking structures, these fenders help to protect both the vessel and the dock from damage when ships berth at an angle.

Advantages of Using Rubber Fenders

The adoption of rubber fenders in ship docking operations comes with numerous advantages

- Protection Rubber fenders significantly reduce the risk of damage to vessels and docking infrastructures, which can be costly to repair. By absorbing impact energy, they provide a buffer that enhances safety for ships and dock workers alike.

- Durability High-quality rubber fenders are built to withstand extreme weather conditions, heavy loads, and wear over time. This longevity means that they can provide effective protection over many years without frequent replacements.

- Cost-Effectiveness By preventing damage to both vessels and docking facilities, rubber fenders can save shipping companies substantial repair costs. Additionally, their long lifespan means that operational expenditures are kept in check.

- Versatility The various types of rubber fenders available allow for customization based on specific needs, such as vessel size and operational environment. This versatility ensures that the right fender can be selected for any given situation.

Conclusion

In conclusion, ship rubber fenders are essential components in maritime safety and operational efficiency. Their ability to absorb and dissipate impact energy makes them invaluable in protecting both ships and docking facilities from potential damage. With advancements in materials and design, rubber fenders continue to evolve, offering enhanced protection and performance. As global shipping activities increase, the role of rubber fenders will undoubtedly remain critical in ensuring safe and efficient maritime operations. By investing in the right fender systems, shipping companies can not only protect their assets but also contribute to the overall safety and sustainability of the maritime industry.