Jun . 15, 2024 18:31 Back to list

Silicone Rubber Door & Window Seals Manufacturer

Silicone Rubber Door and Window Seals A Comprehensive Factory Guide

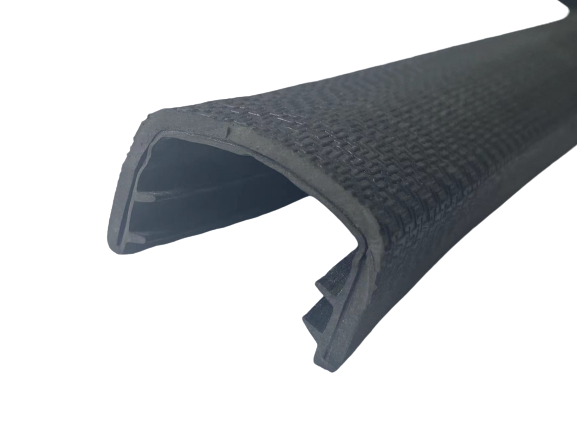

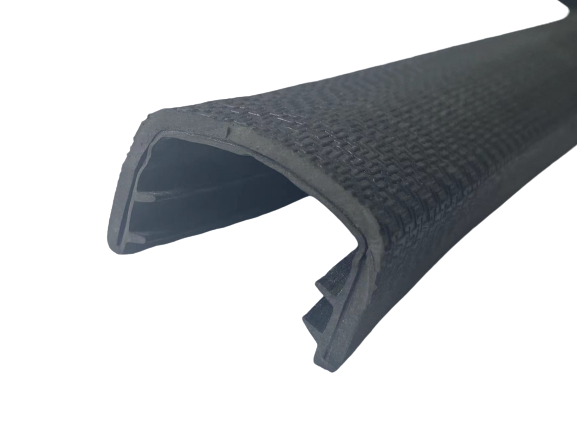

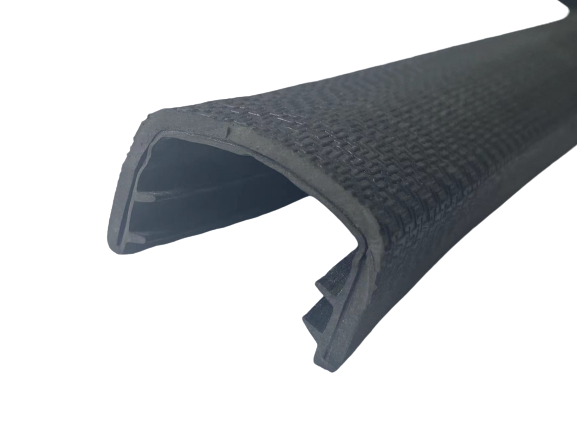

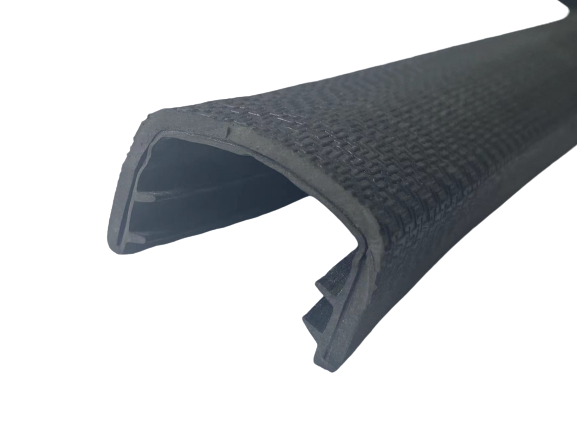

Silicone rubber door and window seals are essential components in maintaining energy efficiency, comfort, and safety within buildings. These seals prevent air, water, dust, and noise from penetrating the gaps between doors and windows, ensuring a comfortable indoor environment while reducing energy loss. In this factory guide, we will explore the key aspects of silicone rubber door and window seals, including their composition, production process, applications, and benefits.

Composition

Silicone rubber door and window seals are typically made from high-quality silicone rubber compounds. These compounds consist of two main components silicone polymer and reinforcing fillers such as carbon black, fumed silica, or titanium dioxide. The silicone polymer provides flexibility, durability, and resistance to extreme temperatures, while the reinforcing fillers enhance the seal's strength, hardness, and wear resistance.

Production Process

The production process of silicone rubber door and window seals involves several steps. First, the silicone rubber compound is mixed and kneaded to ensure proper dispersion of the reinforcing fillers. Next, the compound is extruded into various shapes and sizes using specialized extrusion equipment. After extrusion, the seals undergo a curing process, which involves heating the material at high temperatures to activate the cross-linking reaction and achieve the desired physical properties. Finally, the seals are inspected for quality and packaged for distribution.

Applications

Silicone rubber door and window seals are widely used in various applications, including residential, commercial, and industrial buildings. They are commonly found on doors, windows, skylights, and other openings to provide a tight seal and prevent air leakage. Silicone rubber seals are also used in automotive, aerospace, and marine industries to provide sealing solutions for various components and systems Silicone rubber seals are also used in automotive, aerospace, and marine industries to provide sealing solutions for various components and systems Silicone rubber seals are also used in automotive, aerospace, and marine industries to provide sealing solutions for various components and systems Silicone rubber seals are also used in automotive, aerospace, and marine industries to provide sealing solutions for various components and systems

Silicone rubber seals are also used in automotive, aerospace, and marine industries to provide sealing solutions for various components and systems Silicone rubber seals are also used in automotive, aerospace, and marine industries to provide sealing solutions for various components and systems silicone rubber door and window seals factory.

Benefits

Silicone rubber door and window seals offer numerous benefits, including

1. Energy Efficiency By preventing air leakage, silicone rubber seals help reduce heating and cooling costs by maintaining a consistent indoor temperature.

2. Comfort These seals minimize noise pollution by blocking out external sounds, creating a quiet and peaceful indoor environment.

3. Durability Silicone rubber is highly resistant to UV radiation, ozone, and extreme temperatures, ensuring long-lasting performance and durability.

4. Safety Silicone rubber seals do not emit harmful chemicals or gases, making them safe for use in indoor environments.

5. Easy Installation These seals are designed to be installed quickly and easily, saving time and labor costs.

In conclusion, silicone rubber door and window seals play a crucial role in maintaining energy efficiency, comfort, and safety within buildings. By understanding their composition, production process, applications, and benefits, manufacturers can produce high-quality seals that meet the needs of various industries and applications.

silicone rubber door and window seals factory.

Benefits

Silicone rubber door and window seals offer numerous benefits, including

1. Energy Efficiency By preventing air leakage, silicone rubber seals help reduce heating and cooling costs by maintaining a consistent indoor temperature.

2. Comfort These seals minimize noise pollution by blocking out external sounds, creating a quiet and peaceful indoor environment.

3. Durability Silicone rubber is highly resistant to UV radiation, ozone, and extreme temperatures, ensuring long-lasting performance and durability.

4. Safety Silicone rubber seals do not emit harmful chemicals or gases, making them safe for use in indoor environments.

5. Easy Installation These seals are designed to be installed quickly and easily, saving time and labor costs.

In conclusion, silicone rubber door and window seals play a crucial role in maintaining energy efficiency, comfort, and safety within buildings. By understanding their composition, production process, applications, and benefits, manufacturers can produce high-quality seals that meet the needs of various industries and applications.

Silicone rubber seals are also used in automotive, aerospace, and marine industries to provide sealing solutions for various components and systems Silicone rubber seals are also used in automotive, aerospace, and marine industries to provide sealing solutions for various components and systems

Silicone rubber seals are also used in automotive, aerospace, and marine industries to provide sealing solutions for various components and systems Silicone rubber seals are also used in automotive, aerospace, and marine industries to provide sealing solutions for various components and systems silicone rubber door and window seals factory.

Benefits

Silicone rubber door and window seals offer numerous benefits, including

1. Energy Efficiency By preventing air leakage, silicone rubber seals help reduce heating and cooling costs by maintaining a consistent indoor temperature.

2. Comfort These seals minimize noise pollution by blocking out external sounds, creating a quiet and peaceful indoor environment.

3. Durability Silicone rubber is highly resistant to UV radiation, ozone, and extreme temperatures, ensuring long-lasting performance and durability.

4. Safety Silicone rubber seals do not emit harmful chemicals or gases, making them safe for use in indoor environments.

5. Easy Installation These seals are designed to be installed quickly and easily, saving time and labor costs.

In conclusion, silicone rubber door and window seals play a crucial role in maintaining energy efficiency, comfort, and safety within buildings. By understanding their composition, production process, applications, and benefits, manufacturers can produce high-quality seals that meet the needs of various industries and applications.

silicone rubber door and window seals factory.

Benefits

Silicone rubber door and window seals offer numerous benefits, including

1. Energy Efficiency By preventing air leakage, silicone rubber seals help reduce heating and cooling costs by maintaining a consistent indoor temperature.

2. Comfort These seals minimize noise pollution by blocking out external sounds, creating a quiet and peaceful indoor environment.

3. Durability Silicone rubber is highly resistant to UV radiation, ozone, and extreme temperatures, ensuring long-lasting performance and durability.

4. Safety Silicone rubber seals do not emit harmful chemicals or gases, making them safe for use in indoor environments.

5. Easy Installation These seals are designed to be installed quickly and easily, saving time and labor costs.

In conclusion, silicone rubber door and window seals play a crucial role in maintaining energy efficiency, comfort, and safety within buildings. By understanding their composition, production process, applications, and benefits, manufacturers can produce high-quality seals that meet the needs of various industries and applications.