Nov . 01, 2024 00:46 Back to list

solid neoprene rubber strips for versatile applications and durable performance in various industries

Solid Neoprene Rubber Strips Versatile Solutions for Various Applications

Solid neoprene rubber strips have become increasingly popular across a myriad of industries due to their outstanding properties and versatility. Known for their durability, flexibility, and resistance to environmental factors, these strips serve numerous functions in both commercial and residential settings. This article explores the characteristics, applications, and benefits of solid neoprene rubber strips.

Properties of Neoprene Rubber

Neoprene, the common name for polychloroprene, is a synthetic rubber that exhibits exceptional resilience and strength. Solid neoprene rubber strips are characterized by their excellent chemical resistance, making them suitable for use in harsh environments. They can withstand exposure to oils, fuels, and various chemicals without degrading, making them ideal for industrial applications.

In addition to chemical resistance, neoprene rubber strips are also resistant to water and UV light, ensuring longevity even when exposed to outdoor conditions. Their ability to maintain elasticity under a range of temperatures further enhances their functionality, allowing them to be used in both hot and cold environments.

Applications of Solid Neoprene Rubber Strips

The applications of solid neoprene rubber strips are diverse and widespread. In construction, they serve as reliable seals and gaskets, preventing water leaks and air infiltration. This is particularly important in areas such as windows, doors, and roofs, where they provide insulation and contribute to energy efficiency.

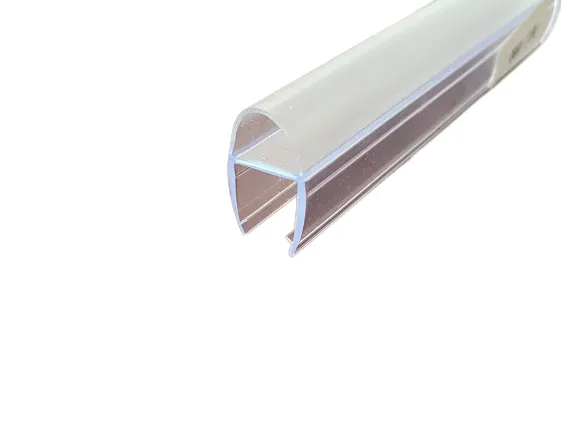

solid neoprene rubber strips

In the automotive industry, neoprene rubber strips are used for weather stripping, ensuring seals around doors and windows to prevent wind and water from entering the vehicle. Additionally, they can be found in marine applications, where they protect boats from wear caused by saltwater and provide cushioning against impacts.

In manufacturing, solid neoprene strips are often utilized as spacers, protectors, or wear pads. Their capacity to absorb shock and vibration makes them essential in machinery and equipment, helping to reduce noise and minimize damage during operation.

Benefits of Using Neoprene Rubber Strips

One of the key benefits of solid neoprene rubber strips is their cost-effectiveness. Their durability means they often last longer than other materials, reducing maintenance and replacement costs over time. Furthermore, the wide availability of neoprene rubber in various thicknesses and sizes allows for easy customization to meet specific project needs.

Another advantage is their ease of installation. Neoprene rubber strips can be cut to the desired length and applied with adhesives or mechanical fasteners, making them user-friendly and accessible for both DIY enthusiasts and professionals.

Conclusion

In conclusion, solid neoprene rubber strips are indispensable materials in a range of applications, providing superior resistance to chemicals, weather, and wear. Their flexibility and ease of use make them a favored choice for construction, automotive, marine, and manufacturing industries. As technology advances and industries evolve, the demand for high-quality materials like solid neoprene rubber strips will likely continue to grow, solidifying their place as essential components in modern applications. Whether for sealing, cushioning, or insulating, these rubber strips offer reliable solutions that enhance efficiency and durability across various domains.