Aug . 06, 2024 12:40 Back to list

The Best Adhesives for Automotive Weather Stripping and Repairing Seals in Your Vehicle

The Importance of Automobile Weather Stripping Adhesive

In the world of automotive manufacturing and repair, one component often overlooked is the weather stripping adhesive. This special adhesive plays a critical role in ensuring that vehicles remain sealed from the elements and maintain optimal interior conditions. Weather stripping itself refers to the strips of material that create seals around doors, windows, trunks, and hoods, preventing water, air, dust, and noise from entering the vehicle. However, its effectiveness largely depends on the quality and performance of the adhesive used to secure it.

The Function of Weather Stripping

To understand the significance of weather stripping adhesive, it is essential first to comprehend the function of weather stripping itself. Weather stripping serves as a barrier against external factors that can affect the car's interior comfort and the overall driving experience. A well-sealed vehicle can retain heat in the winter and keep cool air inside during the summer months. Additionally, it helps minimize noise from the outside, contributing to a quieter ride. Moreover, weather stripping is vital for preventing water ingress, which can lead to mold, mildew, and corrosion over time.

The Role of Adhesive

The adhesive used to bond weather stripping to the vehicle is paramount. It must endure various environmental challenges, including temperature fluctuations, humidity, and exposure to UV light. A high-quality weather stripping adhesive provides strong bonding capabilities to ensure that the strips remain securely in place under these conditions. Furthermore, it must not only be weather-resistant but also flexible enough to withstand the natural movements of the vehicle as it operates on different terrains.

Types of Weather Stripping Adhesives

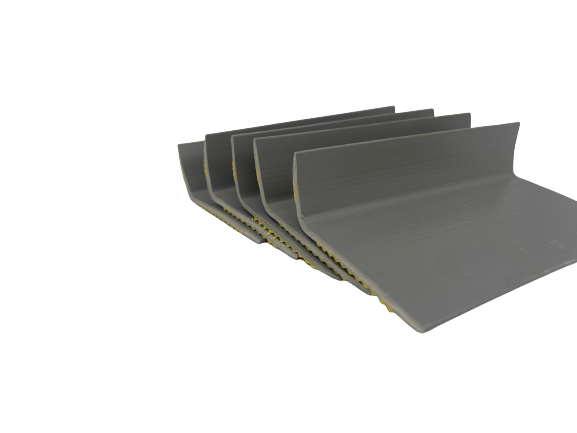

automobile weather stripping adhesive

There are several types of weather stripping adhesives available in the market, each engineered for specific applications. Some commonly used adhesives include rubber cement, silicone adhesive, and polyurethane-based adhesives. Rubber cement is often favored for its quick-drying properties and ease of use, making it ideal for both professionals and DIY enthusiasts. Silicone adhesives excel in resisting moisture and extreme temperatures, while polyurethane adhesives provide robust bonding strengths, making them suitable for high-stress applications.

When choosing an adhesive, it is crucial to consider the compatibility with the weather stripping material and the expected conditions the vehicle will face. Proper surface preparation is also necessary for ensuring a strong bond; this may involve cleaning the surfaces thoroughly to remove any contaminants that could hinder adhesion.

Maintenance and Replacement

Over time, even the best adhesives can degrade due to exposure to elements and wear. Regular inspections of weather stripping and its adhesive are essential, especially for older vehicles. Signs of deterioration may include visible gaps where water can enter, peeling strips, and increased noise levels. In such cases, reconditioning the adhesive or completely replacing the weather stripping may be necessary.

Conclusion

In conclusion, automobile weather stripping adhesive is an understated yet vital component in maintaining the functionality and comfort of a vehicle. By ensuring that weather stripping remains properly adhered, drivers can enjoy a more pleasant driving experience while protecting their vehicles from the elements. As technology progresses, advancements in adhesive formulations continue to enhance the performance and durability of weather stripping solutions. Therefore, whether you're a vehicle manufacturer or a DIY car enthusiast, choosing the right weather stripping adhesive is an investment in the longevity and comfort of your vehicle.