Dec . 12, 2024 10:43 Back to list

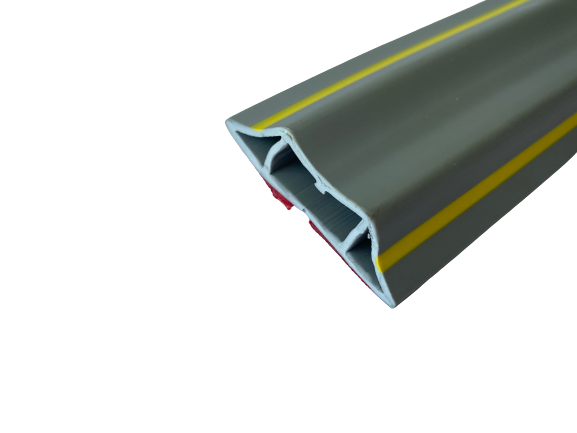

thin rubber sheet roll

The Versatility of Thin Rubber Sheet Rolls

Thin rubber sheet rolls have become increasingly popular in various industries due to their versatility, durability, and cost-effectiveness. Made from high-quality rubber compounds, these rolls can be utilized in a wide range of applications from industrial settings to household use. This article will explore the characteristics, benefits, and applications of thin rubber sheet rolls, shedding light on why they are an essential material in many sectors.

Characteristics of Thin Rubber Sheet Rolls

Thin rubber sheet rolls are typically manufactured in a variety of thicknesses, ranging from 1/16 inch to 1/8 inch, although custom thicknesses can be produced to meet specific requirements. They are made from natural rubber or synthetic rubber materials, including neoprene, EPDM, and nitrile, each offering distinct properties suited for different applications.

One of the primary characteristics of thin rubber sheets is their flexibility. They can easily conform to different shapes and surfaces, making them ideal for sealing and cushioning applications. Additionally, these sheets exhibit excellent resistance to abrasion, wear, and certain chemicals, particularly when using nitrile or EPDM rubber. Their resilience and durability make them suitable for heavy-duty applications, while their lightweight nature allows for easy handling and installation.

Benefits of Using Thin Rubber Sheet Rolls

The benefits of using thin rubber sheet rolls are numerous. Firstly, they offer excellent insulation properties, making them effective in preventing heat transfer and noise pollution. This feature is particularly valuable in manufacturing and construction environments where sound dampening is necessary.

Moreover, thin rubber sheets are cost-effective solutions for many applications. They can be cut to size, minimizing waste, and reducing costs associated with custom fabrication. Their availability in rolls also allows for easier storage and transportation, making them a convenient choice for contractors and manufacturers alike.

thin rubber sheet roll

Thin rubber sheets are also easy to maintain. They can be cleaned with simple detergents and water, ensuring they remain in good condition even after prolonged use. This ease of maintenance, combined with their durability, means that investments in thin rubber sheets yield long-lasting returns.

Applications of Thin Rubber Sheet Rolls

The applications of thin rubber sheet rolls are virtually endless. In the automotive industry, they are used for gaskets, seals, and insulation to improve vehicle performance and comfort. In manufacturing, they serve as conveyor belts, padding, and vibration dampeners.

In the construction sector, thin rubber sheets can be utilized as weatherproofing membranes, roofing materials, and flooring underlayment. Their resistance to moisture and mold makes them ideal for environments where water exposure is a concern.

Additionally, thin rubber sheets are commonly used in packaging and shipping industries as protective liners, cushioning materials, and shock absorbers to safeguard fragile items during transit.

In the realm of DIY projects, homeowners and hobbyists often turn to thin rubber sheets for crafting, soundproofing rooms, or even creating custom mats for various purposes.

Conclusion

In conclusion, thin rubber sheet rolls are a remarkable material with a wide range of applications and benefits. Their versatility, combined with their durability and cost-effectiveness, makes them indispensable across several industries. Whether used in industrial applications, automotive manufacturing, construction, or even home improvement projects, thin rubber sheets continue to prove their value as a reliable and efficient solution for a variety of needs. As technology advances, the potential for innovative uses of thin rubber sheets will undoubtedly expand, further solidifying their role as a foundational material in modern manufacturing and construction.

Next:

Prev: