Aug . 12, 2024 19:38 Back to list

Top Manufacturers of EPDM Composite Sponge Door Seal Strips for Quality Protection Solutions

EPDM Composite Sponge Door Seal Strip Companies An Overview

In today's era of increasing energy efficiency and environmental consciousness, the role of advanced materials in construction is more significant than ever. One such material that has gained prominence is the EPDM (Ethylene Propylene Diene Monomer) composite sponge seal strip. This innovative product is widely used in door sealing applications, helping to maintain thermal efficiency, reduce noise, and improve overall comfort within various indoor environments. Numerous companies specialize in manufacturing EPDM composite sponge door seal strips, contributing to a competitive market that offers diverse solutions tailored to meet specific needs.

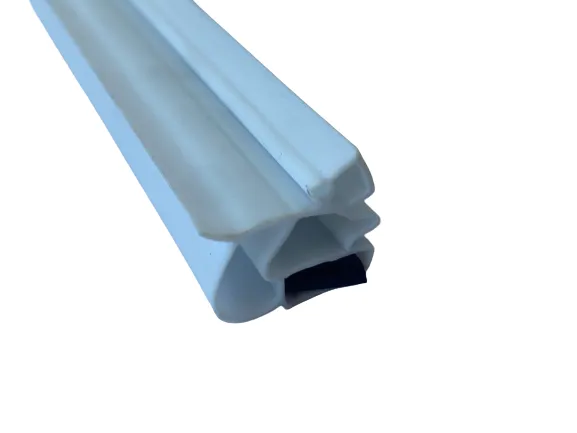

EPDM is a synthetic rubber known for its superior durability and weather resistance. Its remarkable elasticity and resilience make it an ideal choice for sealing applications, particularly in doors and windows. The composite nature of the seal strips, which often includes a sponge backing, adds to their versatility. This combination provides excellent compression set resistance and makes it easier to compress and conform to irregular surfaces, ensuring a tight seal. This characteristic is not only essential for maintaining insulation and energy efficiency but also plays a crucial role in minimizing air and water leakage.

Companies that specialize in EPDM composite sponge door seal strips often focus on quality, innovation, and sustainability. For instance, leading manufacturers utilize advanced extrusion and molding technologies that allow for precise control over the dimensions and properties of the seal strips. This ensures that the products meet the rigorous standards required for various applications, from residential buildings to industrial facilities.

One significant advantage of EPDM composite sponge seal strips is their ability to withstand extreme weather conditions. Whether it’s harsh sunlight, heavy rain, or freezing temperatures, EPDM seals retain their integrity and performance. This longevity reduces the need for frequent replacements, leading to cost savings and lower environmental impact—two factors that resonate well with today's eco-conscious consumers and businesses alike.

epdm composite sponge door seal strip companies

Moreover, many companies are responding to the growing demand for sustainable practices in manufacturing

. Some manufacturers focus on using recycled materials to produce their EPDM sponge seal strips, thereby contributing to a circular economy. These companies not only strive to minimize waste in their production processes but also work to educate their clients about the benefits of choosing eco-friendly products.In addition to standard products, several innovative firms are developing custom solutions tailored to specific client needs. These bespoke seal strips can cater to unique door shapes, sizes, and performance requirements. Whether it’s for a commercial building looking to improve energy efficiency or for a residential property aiming to enhance comfort, these companies have the expertise to provide tailored recommendations.

The importance of partner companies in the supply chain should not be overlooked. Many EPDM composite sponge door seal strip manufacturers form alliances with architects, builders, and contractors, enabling them to provide comprehensive solutions that integrate seamlessly into the building design and construction process. By collaborating with professionals in the field, these manufacturers can stay up to date with industry trends and ensure their products meet evolving standards and regulations.

In conclusion, EPDM composite sponge door seal strips represent a critical component in the quest for energy efficiency and environmental sustainability in building construction. Companies specializing in this product have embraced innovation, quality, and sustainability, providing diverse solutions tailored to meet the myriad needs of their clients. As the industry continues to grow and evolve, these manufacturers play a pivotal role in shaping a more efficient and environmentally-friendly built environment.