Aug . 11, 2024 20:56 Back to list

Top Manufacturers of EPDM Composite Sponge Door Sealing Strips for Effective Insulation Solutions

EPDM Composite Sponge Door Sealing Strip Manufacturers Ensuring Quality and Performance

In today's fast-paced world, where energy efficiency and environmental sustainability are of utmost importance, the significance of high-quality sealing solutions cannot be underestimated. One such innovative product is the EPDM (Ethylene Propylene Diene Monomer) composite sponge door sealing strip, widely used in various industries ranging from construction to automotive. The manufacturers of these sealing strips play a crucial role in delivering products that meet stringent standards of quality, durability, and performance.

The Importance of EPDM in Door Sealing Solutions

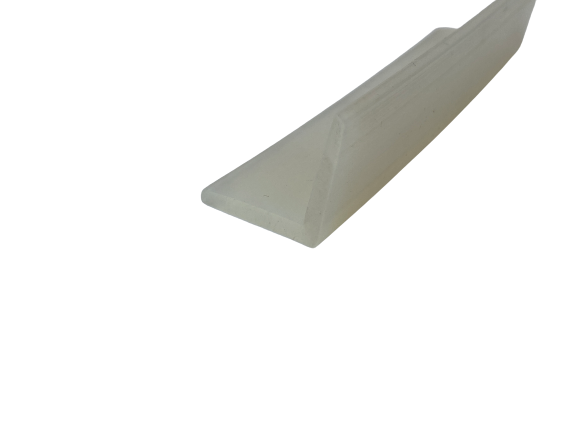

EPDM is a type of synthetic rubber that boasts excellent resistance to heat, ozone, and weathering. Its impressive elasticity and flexibility make it an ideal material for sealing strips. When combined with a sponge structure, EPDM can effectively absorb impacts and provide a tight seal around doors and windows. This helps in preventing air leaks, reducing noise, and enhancing thermal insulation within buildings. Thus, the use of EPDM composite sponge sealing strips is integral to creating energy-efficient spaces that contribute to lower utility bills and increased comfort.

Characteristics of High-Quality Sealing Strips

Manufacturers of EPDM composite sponge door sealing strips focus on several key characteristics to ensure quality and performance

1. Durability High-quality sealing strips should withstand various environmental conditions, including extreme temperatures and excess moisture. EPDM’s inherent properties make it resistant to degradation, ensuring that the sealing strips maintain their effectiveness over time.

2. Flexibility A good sealing strip must be flexible enough to conform to the door frame, providing a snug fit. This is fundamental for creating a barrier against dust, water, and air infiltration.

3. Noise Reduction Effective door seals can significantly reduce noise transmission between rooms, enhancing privacy and comfort. Manufacturers must ensure that their products are designed to minimize sound leakage.

epdm composite sponge door sealing strip manufacturers

4. Ease of Installation Sealing strips should come with user-friendly installation options, such as adhesive backing or easy-to-fix profiles that simplify the fitting process for builders and DIY enthusiasts alike.

The Role of Manufacturers

Manufacturers specializing in EPDM composite sponge door sealing strips are at the forefront of developing innovative sealing solutions. They are dedicated to high-quality control standards, ensuring that every product meets or exceeds industry regulations. This commitment to excellence is crucial, as the effectiveness of sealing strips significantly impacts overall building performance.

Additionally, many manufacturers offer customized solutions to meet specific customer needs. They collaborate with clients to design sealing strips that cater to unique applications or specific environmental requirements. This personalized approach not only enhances customer satisfaction but also fosters long-term partnerships.

Market Trends and Innovations

The market for EPDM composite sponge door sealing strips has seen a surge in demand driven by rising awareness of energy efficiency and sustainable building practices. Manufacturers are increasingly adopting eco-friendly production processes and materials to appeal to environmentally conscious consumers. Innovations such as enhanced adhesive technologies and advanced manufacturing techniques are also paving the way for the development of more effective sealing solutions.

Conclusion

In summary, EPDM composite sponge door sealing strip manufacturers play a vital role in the construction and automotive industries, providing essential products that enhance energy efficiency, comfort, and overall building performance. As the demand for high-quality sealing solutions continues to grow, these manufacturers are committed to innovation and quality, ensuring that their products meet the evolving needs of consumers and contribute to sustainable building practices. By choosing EPDM sealing solutions, customers can be assured of durability, effectiveness, and long-lasting performance.