Aug . 06, 2024 09:26 Back to list

Top Manufacturers of Rubber Seals for Automotive Windows and Their Key Features

Understanding the Importance of Car Window Rubber Seal Factories

The automotive industry has been an essential part of global manufacturing, with various components playing a crucial role in vehicle performance, safety, and comfort. Among these components, the car window rubber seal, often overlooked, is vital for a vehicle's overall integrity. Car window rubber seal factories specialize in the production of these essential parts, ensuring that vehicles are not only functional but also comfortable and safe for passengers.

What is a Car Window Rubber Seal?

A car window rubber seal, also known as a weatherstrip or gasket, is a flexible strip typically made from synthetic rubber or other durable materials. Its primary function is to create a tight seal around the car windows, preventing water, dust, and noise from entering the vehicle. Additionally, these seals contribute to the structural stability of the car, enhancing its aerodynamics and reducing wind resistance.

The Role of Car Window Rubber Seal Factories

Car window rubber seal factories are specialized manufacturing units dedicated to producing these essential automotive components. These factories typically employ advanced production techniques and cutting-edge technology to ensure high-quality output. The production process includes the careful selection of raw materials, precise molding, and rigorous quality control measures.

1. Raw Material Selection The quality of rubber used for manufacturing seals is critical, as it must withstand various environmental conditions. Factories carefully select compounds that offer durability, flexibility, and resistance to UV light, chemicals, and extreme temperatures.

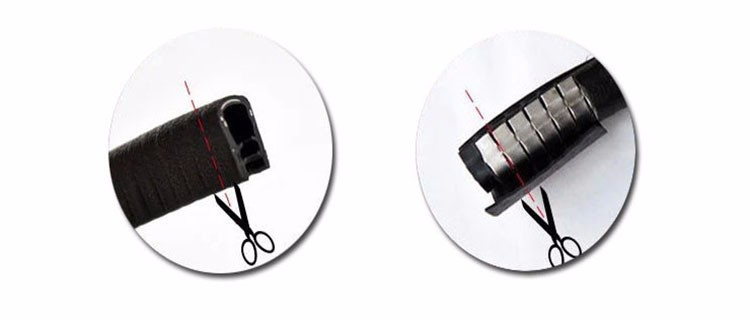

2. Manufacturing Process The manufacturing process often involves extrusion, molding, and cutting. Each method requires precision to ensure that the seals fit perfectly in the designated window frames. Factories may employ automated machinery to increase efficiency and maintain consistent product quality.

car window rubber seal factories

3. Quality Control Quality assurance is a significant focus in these factories, as defective rubber seals can lead to severe consequences, such as leaks or increased cabin noise. Factories implement rigorous testing protocols, including water resistance tests, durability evaluations, and environmental simulations, to ensure compliance with industry standards.

The Importance of Innovation

As the automotive industry evolves, so does the need for innovation in manufacturing processes. Car window rubber seal factories are increasingly adopting new materials and technologies to enhance product performance. For instance, the integration of eco-friendly materials aligns with the growing demand for sustainable automotive solutions. Additionally, advancements in manufacturing technologies, such as 3D printing, allow for more complex designs and quicker prototyping, ultimately reducing production time and costs.

Challenges Faced by Rubber Seal Manufacturers

Despite the advancements, car window rubber seal factories face various challenges. The competitive nature of the automotive industry demands that manufacturers continuously improve their products while managing costs. Supply chain disruptions, fluctuating raw material prices, and stringent regulatory requirements can also complicate the manufacturing process. Furthermore, as electric vehicles and autonomous driving technology become more prevalent, factories must adapt to new specifications and requirements that these advancements bring.

Conclusion

In conclusion, car window rubber seal factories play a crucial role in the automotive manufacturing ecosystem. Their commitment to quality, innovation, and responsiveness to industry changes ensures that vehicles are equipped with reliable and effective window seals. As automotive technology continues to evolve, these factories will remain integral to meeting the demands of modern vehicles, contributing to consumer safety and satisfaction. Investing in advanced production methods and sustainable practices will be essential for these factories to thrive in the competitive automotive landscape of the future.