Aug . 06, 2024 14:53 Back to list

Top Quality EPDM Gaskets for Oil Tanks to Ensure a Reliable and Leak-Proof Seal

The Importance of Selecting the Best EPDM Oil Tank Gasket

In various industries, the safe storage and transportation of oil and petroleum products are critical to ensuring operational efficiency and environmental protection. An often overlooked yet vital component in this process is the oil tank gasket. Among the materials used for gaskets, EPDM (Ethylene Propylene Diene Monomer) has emerged as a leading choice due to its numerous advantageous properties. Selecting the best EPDM oil tank gasket can significantly impact performance and reliability.

Why Choose EPDM?

EPDM is a synthetic rubber that exhibits exceptional resilience and durability. It is highly resistant to heat, ozone, and harsh weather conditions, making it ideal for outdoor applications where tanks may be exposed to the elements. Additionally, EPDM is resistant to aging, ensuring a long lifespan even in demanding environments. These characteristics make EPDM gaskets an excellent choice for oil tanks, which are often subjected to fluctuating temperatures and pressures.

One of the most significant advantages of using EPDM as a gasket material is its excellent resistance to various chemicals. While traditional rubber materials may degrade when exposed to petroleum products, EPDM maintains its integrity, ensuring a secure seal that can prevent leaks and spills. This is imperative not only for the safety of personnel but also for protecting the environment from contamination.

Key Features of High-Quality EPDM Oil Tank Gaskets

When selecting the best EPDM oil tank gasket, there are several key features to consider

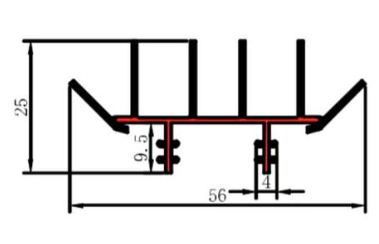

1. Thickness and Compression The thickness of the gasket is crucial. It must be thick enough to compress adequately when installed, forming a tight seal. However, it should not be overly thick, as this can lead to improper sealing and potential leaks.

best epdm oil tank gasket

2. Temperature Tolerance EPDM gaskets should be able to perform well in a range of temperatures. This is critical for oil tanks, which may experience extreme heat or cold depending on the environment.

3. Chemical Compatibility Ensure that the EPDM material you choose is specifically formulated to withstand the types of oil and chemicals it will encounter. This will prevent premature failure and guarantee the longevity of the gasket.

4. Surface Finish The surface texture of the gasket can affect sealing capabilities. A smooth finish may work in some applications, while a textured finish could enhance the grip and seal in others. Choosing the right surface finish is essential.

5. Custom Sizing Oil tanks come in various shapes and sizes. Gaskets should be customizable to ensure a perfect fit, minimizing the risk of leaks.

Installation and Maintenance

Proper installation of the EPDM gasket is key to its effectiveness. All surfaces should be clean and free of debris, and the gasket should be aligned correctly to ensure a uniform seal. Regular maintenance checks are recommended to monitor the condition of the gasket and identify any signs of wear or damage early on.

In conclusion, selecting the best EPDM oil tank gasket is fundamental in achieving a safe and efficient oil storage solution. With its superior durability, chemical resistance, and long lifespan, EPDM is the go-to material for ensuring that oil tanks remain secure and leak-free. By considering the essential features and maintaining proper installation and care, industries can protect both their resources and the environment, promoting a more sustainable approach to oil management.