Nov . 05, 2024 07:28 Back to list

u-shaped epdm automotive fuel tank gasket manufacturer

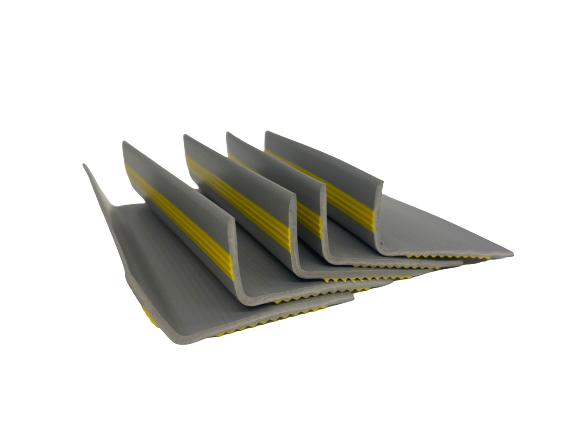

U-Shaped EPDM Automotive Fuel Tank Gasket Manufacturer Ensuring Quality and Reliability

In the automotive industry, the importance of high-quality sealing solutions cannot be overstated, especially when it comes to critical components such as fuel tanks. A vital player in this landscape is the U-shaped EPDM automotive fuel tank gasket, which offers superior durability, flexibility, and resistance to various environmental factors. This article explores the significance of these gaskets, their manufacturing process, and the key manufacturers who specialize in this essential automotive component.

Understanding EPDM Material

EPDM, or Ethylene Propylene Diene Monomer, is a type of synthetic rubber known for its excellent weather resistance, UV stability, and thermal stability. This makes it an ideal choice for automotive applications, particularly in sealing solutions exposed to varying temperatures and environmental elements. The U-shaped design of the gasket enhances its ability to accommodate fluctuations in fuel tank contours, ensuring a tight and secure seal that prevents leaks and contamination.

The Need for High-Quality Gaskets

In automotive fuel systems, maintaining an airtight seal is crucial. Leaks can lead to fuel evaporation, which not only results in economic losses but also environmental hazards. Furthermore, improper sealing can lead to engine performance issues, compromising the vehicle's efficiency and safety. OEMs (Original Equipment Manufacturers) and aftermarket suppliers need to rely on high-quality gaskets to uphold these standards. Thus, the demand for reliable manufacturers of U-shaped EPDM automotive fuel tank gaskets is steadily increasing.

The Manufacturing Process

The production of U-shaped EPDM automotive fuel tank gaskets involves several key processes

1. Material Selection High-grade EPDM rubber is sourced from dependable suppliers to ensure quality and consistency. The material is often tested for its physical properties, including tensile strength, elongation, and resistance to oils and fuels.

2. Design and Engineering Gasket manufacturers rely on advanced design software to create precise specifications to meet OEM requirements. The U-shape design is engineered to provide optimal sealing performance, allowing for effective compression when installed.

3. Molding and Curing The selected EPDM material is processed through a molding technique, commonly compression or injection molding. This process shapes the gasket into its final form. Once molded, the gaskets undergo curing, a critical step that enhances their mechanical properties and resilience.

u-shaped epdm automotive fuel tank gasket manufacturer

4. Quality Control Every batch of gaskets is subjected to rigorous testing. This includes checks for dimensional accuracy, tensile strength, and flexibility. Manufacturers may also conduct environmental tests to simulate conditions the gaskets will face in real-world applications.

5. Supply Chain Management Efficient logistics play a crucial role in gasket manufacturing. Timely delivery of raw materials and the ability to supply finished products promptly to OEMs and aftermarket distributors ensure that manufacturers maintain a competitive edge in the market.

Choosing the Right Manufacturer

When selecting a U-shaped EPDM automotive fuel tank gasket manufacturer, several factors should be considered

- Experience and Reputation Choose a manufacturer with a proven track record in producing high-quality automotive components.

- Certifications Ensure the manufacturer adheres to industry standards and certifications, such as ISO 9001, which guarantees quality management practices.

- Customization Options The ability to customize gaskets based on specific vehicle requirements offers significant advantages, especially for niche applications.

- Customer Support A responsive and knowledgeable customer support team can assist with technical queries and ensure that clients receive the best products for their needs.

Conclusion

In conclusion, U-shaped EPDM automotive fuel tank gaskets play a pivotal role in ensuring the reliability and performance of fuel systems in vehicles. As the automotive industry advances towards more stringent environmental and efficiency standards, the demand for high-quality sealing solutions continues to grow. Manufacturers that invest in robust materials, advanced manufacturing processes, and strong quality control measures will be instrumental in shaping the future of automotive sealing technology. By fostering partnerships with reputable gasket manufacturers, automotive companies can ensure their vehicles are equipped for durability and reliability on the road.