Aug . 13, 2024 10:12 Back to list

Understanding CE Certification for EPDM Rubber Sheets and Their Applications in Various Industries

Understanding CE Certification for EPDM Rubber Sheets

In today's increasingly regulated marketplace, the significance of certifications such as CE (Conformité Européenne) cannot be overstated. This is particularly true for materials like EPDM (Ethylene Propylene Diene Monomer) rubber sheets, which are extensively used in various industrial and commercial applications due to their excellent durability, temperature resistance, and versatility. This article delves into the implications of CE certification for EPDM rubber sheets, why it matters, and what it entails.

What is EPDM Rubber?

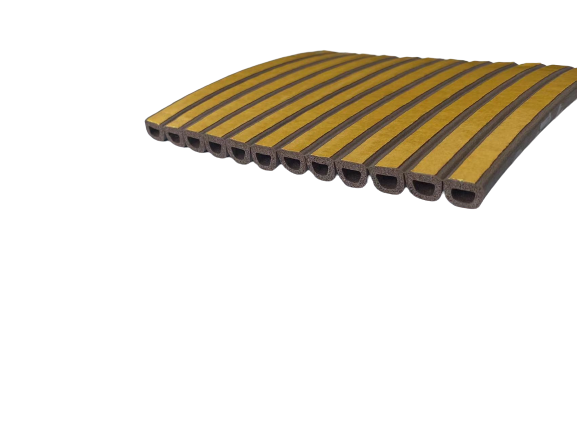

EPDM rubber is a type of synthetic rubber that is widely recognized for its outstanding resistance to heat, ozone, and weathering. This elastomer is favored in sectors ranging from automotive to construction, where it is used for applications such as roofing membranes, seals, gaskets, and electrical insulation. Its elasticity and durability also make it a popular choice for automotive parts, such as hoses and belts.

The Importance of CE Certification

CE certification signifies that a product meets the health, safety, and environmental protection standards set by the European Union (EU). For manufacturers and suppliers of EPDM rubber sheets, obtaining CE certification implies that their products have been assessed and comply with relevant EU directives. This is not only vital for legal compliance but also boosts consumer confidence in the quality and safety of the product.

1. Market Access CE certification is often a prerequisite for entering the European market. Without it, manufacturers may find their products prohibited from sale within EU member states, significantly limiting their market opportunities.

2. Consumer Trust Certification indicates that a product has undergone rigorous testing and meets high standards of quality. As consumers become more aware of product safety and environmental impact, having CE certification can enhance a manufacturer's reputation and increase market competitiveness.

3. Liability and Risk Management By adhering to established safety standards, manufacturers reduce the risk of liability claims related to product failures or safety incidents. CE certification provides an added layer of protection, ensuring that the products they provide are both safe and reliable.

ce certification epdm rubber sheet

The CE Certification Process for EPDM Rubber Sheets

Achieving CE certification involves several key steps

1. Determining Applicable Directives The first step is to identify which EU directives apply to EPDM rubber products. This could include directives related to health and safety, for instance, the Low Voltage Directive (LVD) or the European Regulation on Chemicals (REACH).

2. Product Testing Manufacturers may need to conduct thorough testing to demonstrate compliance with the relevant standards. This can include assessments of mechanical properties, resistance to aging, and reaction to environmental factors.

3. Technical Documentation Creating comprehensive technical documentation is crucial. This document must outline the design, manufacturing processes, and tested characteristics of the rubber sheets.

4. Notified Body Assessment Depending on the type of product and the associated risks, a third-party assessment by a notified body may be required. This independent organization will evaluate the product to ensure it meets EU standards.

5. Issuing the Declaration of Conformity Once all requirements are met, manufacturers must draft a Declaration of Conformity, affirming that their EPDM rubber sheets comply with the necessary EU legislation. They can then affix the CE mark to their products, allowing them to be marketed in the EU.

Conclusion

In conclusion, CE certification for EPDM rubber sheets is an essential aspect of modern manufacturing that signals quality and safety to both market stakeholders and consumers. As global trade continues to expand, understanding and integrating such certifications will not only ensure compliance with regulatory standards but will also foster trust and recognition in the marketplace. Manufacturers must prioritize this certification process to enhance their competitiveness and meet the growing demands for safety and environmental responsibility in product offerings.