Tag/epdm doors and windows rubber sea fbg

-

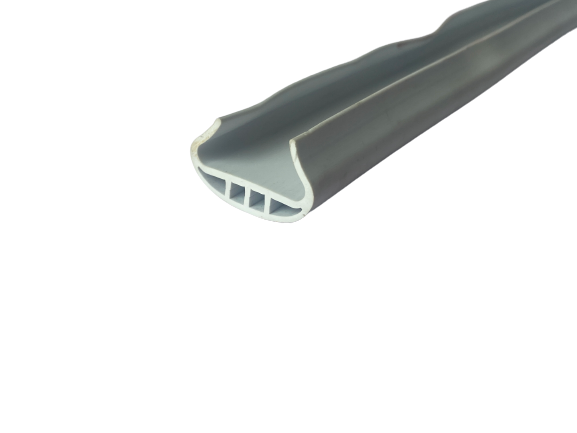

D-type ship anti-collision sealing strip

D-type ship anti-collision sealing strip -

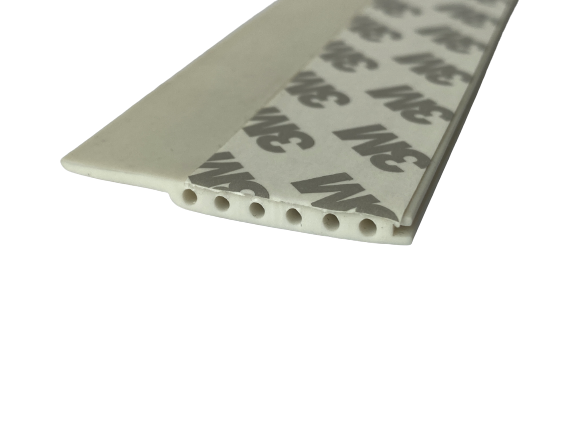

Self adhesive door bottom plug sealing strip

Self adhesive door bottom plug sealing strip -

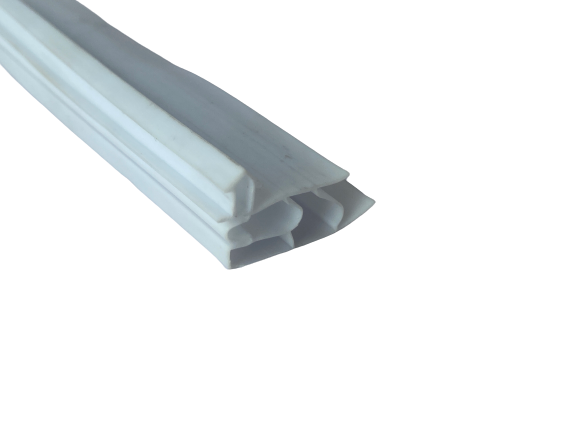

Door Bottom Sealing Strip

Door Bottom Sealing Strip -

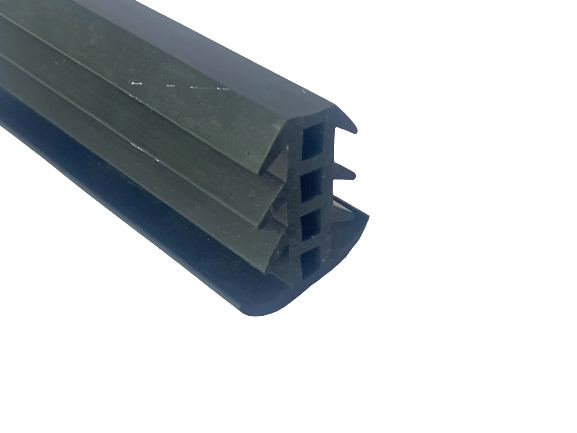

E-type silicone rubber sealing strip

E-type silicone rubber sealing strip -

Garage door bottom sealing strip

Garage door bottom sealing strip -

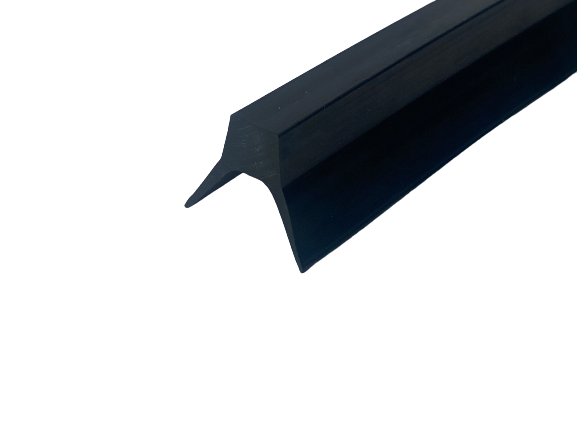

L-type transparent silicone rubber sealing strip

L-type transparent silicone rubber sealing strip -

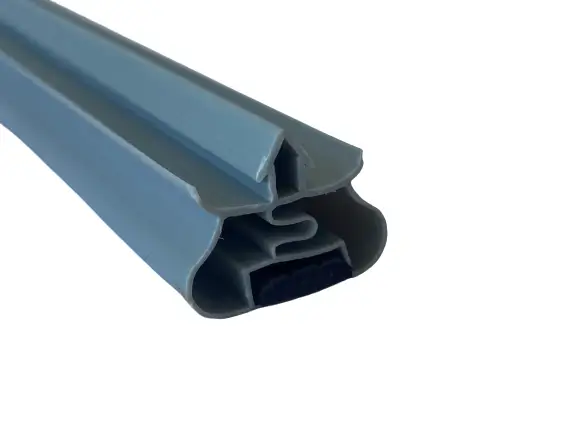

PVC plastic gasket strip for refrigerators

PVC plastic gasket strip for refrigerators -

Shower Door Bottom Sealing Strip

Shower Door Bottom Sealing Strip -

silicone foam sealing strip

silicone foam sealing strip -

Silicone rubber door and window sealing strip

Silicone rubber door and window sealing strip

Produtct Title

epdm doors and windows rubber sea fbg-

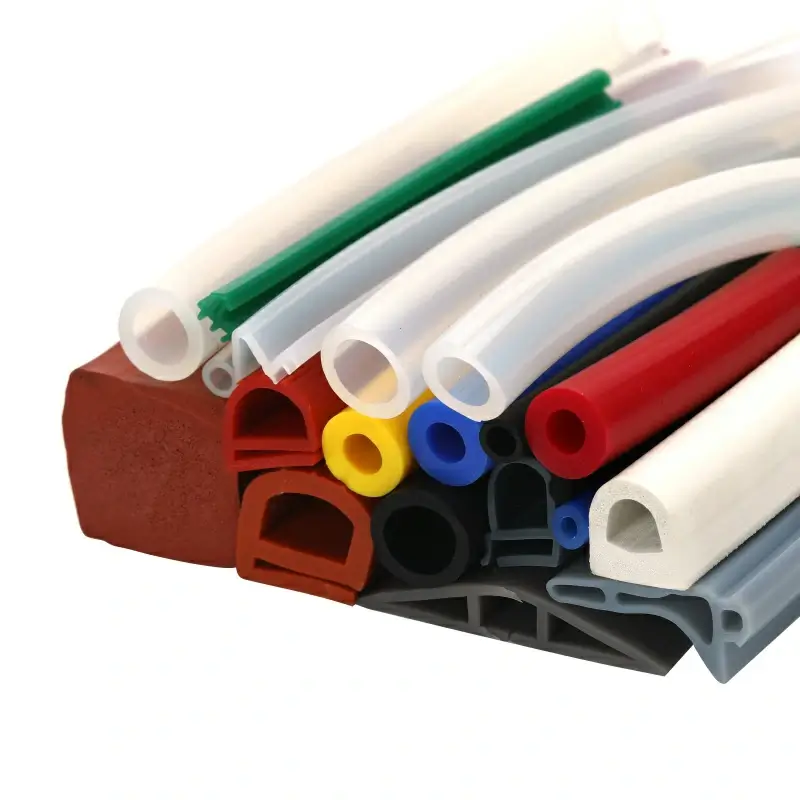

silicone rubber sealing strip

-

Customizable silicone rubber sealing strip

-

T-shaped photovoltaic solar panel sealing strip

-

T-type photovoltaic panel gap adhesive strip

-

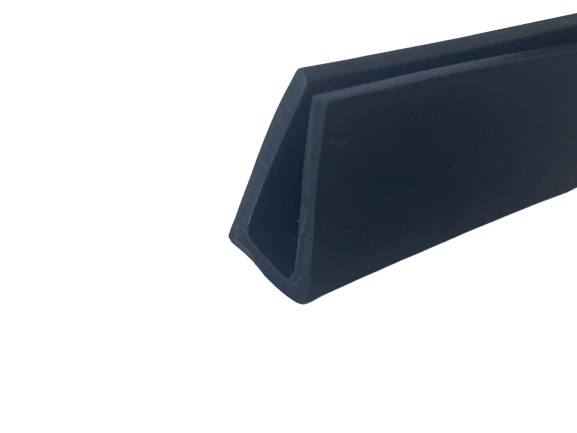

U-shaped door bottom sealing strip

-

U-shaped silicone sealing strip

-

Customizable silicone rubber sealing strip profiles

-

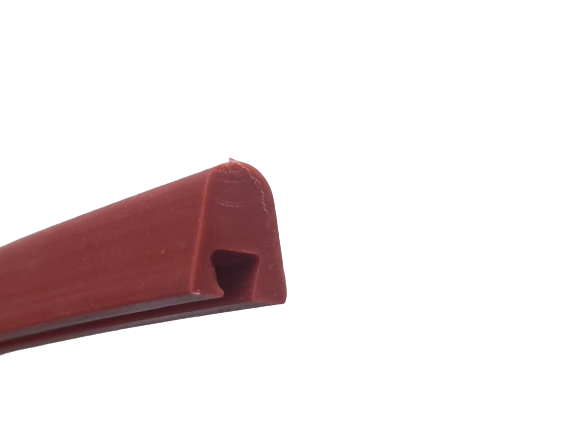

Customizable silicone rubber sealing strip for oven door

-

Customizable soundproof door sealing strip

-

D-Shaped Silicone Sealing Strip

-

self-adhesive D-type EPDM foam sealing strip

-

PVC Bathroom Door Sealing Strip

-

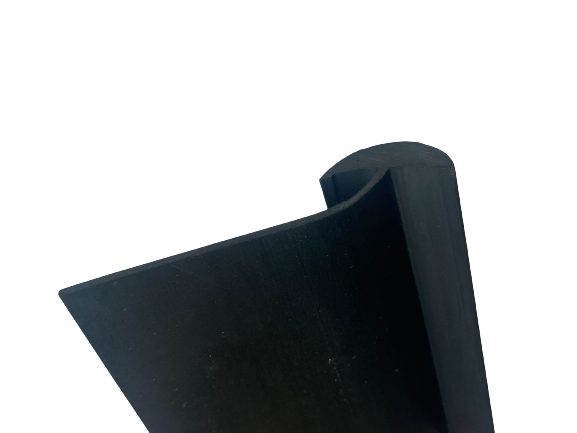

Industrial flexible EPDM rubber sheet roll

-

Refrigerator PVC rubber plastic gasket strip

Related News

-

2025-01-14Characteristics and classification of automobile sealing stripsThe rubber plate has high hardness. It is a sheet product with a certain thickness and a large area, which is made of rubber as the main material (including fabric, metal sheet and other reinforcing materials) and vulcanized. It is called rubber plate for short. In recent years, with the rapid development of the construction industry and the continuous improvement of people's living standards, rubber products show its strong vitality. For example, in the construction industry, at present, most buildings use cement prefabricated slabs. For example, laying rubber slabs on the floor can reduce the noise and improve the floor life. The rubber plate can also produce various density rubber window strips, which can effectively eliminate the problem of air and rain leakage. With the development and change of production and living needs, rubber sheets can be produced in black, gray, green, blue and other colors to meet the needs of different enterprises and life.

-

2024-11-22Standard introduction of rubber sealing stripWhen it comes to rubber sealing strip, we must be familiar with it, because this small thing is indispensable for sealing in our daily life. The most common are the doors and windows in our families, the figure of rubber seals, and the existence of rubber seals in our daily mechanical products. Even the "family" with rubber seals in cars and ships. Although rubber sealing strips are widely used, do you know the standard of rubber sealing strips? It doesn't matter what I don't know. Today, I will introduce you the standard of rubber sealing strip.

-

2024-11-22Standard introduction of rubber sealing stripWhen it comes to rubber sealing strip, we must be familiar with it, because this small thing is indispensable for sealing in our daily life. The most common are the doors and windows in our families, the figure of rubber seals, and the existence of rubber seals in our daily mechanical products. Even the "family" with rubber seals in cars and ships. Although rubber sealing strips are widely used, do you know the standard of rubber sealing strips? It doesn't matter what I don't know. Today, I will introduce you the standard of rubber sealing strip.

-

2024-11-22Standard introduction of rubber sealing stripWhen it comes to rubber sealing strip, we must be familiar with it, because this small thing is indispensable for sealing in our daily life. The most common are the doors and windows in our families, the figure of rubber seals, and the existence of rubber seals in our daily mechanical products. Even the "family" with rubber seals in cars and ships. Although rubber sealing strips are widely used, do you know the standard of rubber sealing strips? It doesn't matter what I don't know. Today, I will introduce you the standard of rubber sealing strip.

-

2025-01-14Standard introduction of rubber sealing stripWhen it comes to rubber sealing strip, we must be familiar with it, because this small thing is indispensable for sealing in our daily life. The most common are the doors and windows in our families, the figure of rubber seals, and the existence of rubber seals in our daily mechanical products. Even the "family" with rubber seals in cars and ships. Although rubber sealing strips are widely used, do you know the standard of rubber sealing strips? It doesn't matter what I don't know. Today, I will introduce you the standard of rubber sealing strip.

-

2025-01-14Characteristics and classification of automobile sealing stripsThe automobile sealing strip has the function of filling various gaps and gaps between the components of the vehicle body, and has the functions of shock absorption, water prevention, dust prevention, sound insulation, decoration, etc., to improve the comfort of the driving experience and protect the vehicle body.

-

2025-01-14Advantages and Disadvantages of PVC/EPDM/TPV/TPE Automotive Sealing Strip MaterialsA sealing strip is a product that seals something to prevent it from being easily opened, providing shock absorption, waterproofing, sound insulation, insulation, dust prevention, and fixation. With the development of the automotive industry, the importance of beautiful, environmentally friendly, and comfortable functions of sealing strips is becoming increasingly prominent, and the demand for automotive sealing strip materials is also increasing. What kind of sealing strip material is good? Each sealing strip manufacturer has their own rhetoric. The current automotive sealing strip materials mainly include four types: PVC sealing strip, EPDM sealing strip, TPV sealing strip, and TPE sealing strip. Below, we will analyze the advantages and disadvantages of these four automotive sealing strip materials.

-

2025-01-14Silicone sealing stripSealing strips have been applied to various industries such as automobiles, doors and windows, cabinets, refrigerators, containers, etc. According to the requirements of different industries, unique products such as automotive sealing strips, mechanical sealing strips, and door and window sealing strips have been developed. Therefore, they are widely used in sealing industries such as electronics and electricians, lighting fixtures, pharmaceuticals, chemicals, mechanical equipment, textile and chemical fibers, and automobiles.

-

2025-01-14What are the materials of door and window sealant strips?The main function of door and window sealing strips is to ensure the perfect water tightness, air tightness, and wind pressure resistance of door and window and curtain wall systems. In addition, they can also play a crucial role in sound insulation, noise reduction, dust prevention, and energy conservation for a perfect door and window system.

-

2025-01-14Daily decoration: which of the three common sealing strips is cost-effective and easy to use?If your door has a large crack, air leakage, no sound insulation, no insulation, and occasional small Qiang shuttling back and forth, it's time to add a sealing strip to the door. There are currently three common types of sealing strips on the market, each with its own advantages and disadvantages. Today, I will organize and analyze them for everyone.

-

2025-01-14How to distinguish between silicone and silicone rubberWhen silica gel is burned, it will not ignite an open flame and is white smoke, gray is white, rubber is black smoke, gray is black, and it smells very bad.

-

2025-01-14How to select door and window sealing strips?Many friends pay attention to quality when purchasing doors and windows, but they often overlook the door and window sealing strip. It should be noted that although the sealing strip is inconspicuous, it is also very important, and it has a great impact on the use of doors and windows!

-

2025-01-14Advantages of News PU Encapsulated Sealing StripWhat is PU encapsulated sealing strip?The wrapped

-

2025-01-14Introduction and Analysis of PU Magnetic Sealing StripPU magnetic sealing strips are an essential component in various industries, serving as a reliabl

-

2025-01-14Characteristics and applications of ship sealing stripsShip sealing strip is a special material used to seal different parts of a ship. Its main charact

-

2024-11-22Ship sealing strip-Key Differences Between Shipping And Moving TapeYou may be thinking that all tape is made the same as long as it’s sticky enough to keep the corrugated carton shut. Although tape’s main purpose is to adhere to and seal the carton, there are actually several differences between shipping and moving tape. These differences are important to understand, so you can choose the carton sealing tape that will work best for your packaging and shipping application.

-

2024-11-22Ship sealing strip-Shipping Container Door Seals: Fundamentals And Replacement GuideCargo containers are vital in transporting import and export products by ship, train, or truck. Shipping container door seals are essential elements of these cargo containers. However, It is important to note that these ships, trains, or trucks travel through all types of weather and natural obstacles. Heavy winds, rain, or snow can be common natural obstacles. Therefore, shipping container door seals are mandatory to prevent water, air, or snow leakage. So, it is crucial to understand the fundamentals of container door gaskets.Previously, we learned about different types of seal strips and their shapes. The article’s name was “Seal strip shapes: The most common shapes in all applications.” You learned about a particular seal strip shape, which is a shape seal strip. This type of seal is the most common type used in marine applications. However, other seal strip shapes are also used in those applications, but not as much as the J shape.This article will introduce you to the fundamentals of shipping container door seals. In addition, you will also learn some basic information related to cargo containers. Later, we will bring some of the most famous shipping container door seals that might be ideal for every cargo container.

-

2024-11-22Ship sealing strip-Seal Strips Vs Rubber GasketsBoth Rubber strips and gaskets have different shapes and sizes depending on the purpose of the applications. Let’s introduce the most common rubber shapes and sizes.Seal strips: Seal strips come in many shapes and sizes. The most common rubber shapes are typical d shape rubber seals, double d shape rubber seals, closed D shape rubber seals, t-shape rubber seals, U-shape extrusion NBR nitrile rubber seals, b-shaped, v, h, I, c, J, and x-shaped rubber seal strips. Besides, seal strips have other unique designs for cabinets, windows, and doors as weather stripping. In addition, there are complex shapes specially designed for some applications. Such as seal strips for glass shower doors, car window seals, window rubber strips for marine ships, rubber water stop for concrete joints, EPDM seals for the automotive windshield, heat-resistant extruded rubber sealing strips for automotive parts, windscreen rubber seals, etc.Rubber gaskets: The common rubber gasket shapes are O-rings or circle gaskets, Mickey Mouse gaskets, blanking gaskets, tabbed gaskets, fiber washers, paper gaskets, cylinder head gaskets, rectangular picture frame gaskets, full-faced flange gasket, manifold style gasket. However, gasket design depends on industrial usage, budget, and chemical and physical parameters. Based on these parameters, rubber gaskets have common shapes: sheet gaskets, solid gaskets, spiral wounds, constant seating, double-jacket, cam profile gasket, fishbone, and flange gasket. Other than these, some complex rubber gasket designs are for special applications.

-

2024-11-22Home sealing strip-Providing High-Quality Door and Window Weather SealDrafty windows and doors can be a significant problem in older homes and lead to higher-than-normal heating and energy bills. Thankfully Fixhome is here to help. We offer high-quality weather seal products to help close any gaps in your windows and doors. This helps to keep out the elements, making it easier for you to heat or cool your home. Our company offers a wide range of window and door weather strips that are ideal for a large assortment of applications and projects. To learn more about the door and window weather strips we have to offer, reach out to our office. We are always happy to help you find the perfect weather sealing solution for your home.

-

2024-11-22Home sealing strip-Choosing WeatherstrippingChoose a type of weatherstripping that will withstand the friction, weather, temperature changes, and wear and tear associated with its location. For example, when applied to a door bottom or threshold, weatherstripping could drag on carpet or erode as a result of foot traffic. Weatherstripping in a window sash must accommodate the sliding of panes -- up and down, sideways, or out. The weatherstripping you choose should seal well when the door or window is closed but allow it to open freely.Choose a product for each specific location. Felt and open-cell foams tend to be inexpensive, susceptible to weather, visible, and inefficient at blocking airflow. However, the ease of applying these materials may make them valuable in low-traffic areas. Vinyl, which is slightly more expensive, holds up well and resists moisture. Metals (bronze, copper, stainless steel, and aluminum) last for years and are affordable. Metal weatherstripping can also provide a nice touch to older homes where vinyl might seem out of place.You can use more than one type of weatherstripping to seal an irregularly shaped space. Also take durability into account when comparing costs. See table below for information about the common types of weatherstripping.

Related Search

- china ship sealing strip

- china marine sealing strip

- china home sealing strip

- china household sealing strip

- china household seal strip

- china epdm rubber sheet

- china rubber sealing strip for car doors

- china car door rubber seal strip

- china rubber sealing strip for car window

- china car window rubber seal

- china door and window sealing strip

- china door seal

- china rubber sealing strip for doors and windows

- china rubber seals for doors and windows

- china ship anti-collision sealing strip

- china ship's anti-collision seal

- china ship anti-collision rubber sealing strip

- china marine fender rubber sealing strip

- china marine fender sealing strip

- china ship fender seal

- china pvc sealing strip for shower door

- china shower door pvc seal strip

- china refrigerator door silicone rubber sealing strip

- china silicone rubber seal strip for refrigerator door

- china silicone rubber sealing strip for oven door

- china silicone rubber seal strip for oven door

- china nbr rubber 1-20mm rubber plate

- china nbr rubber 1~20mm rubber sheet

- china multi color pvc door rubber sealing strip

- china sound insulation pvc door rubber sealing strip