Mar . 28, 2023 11:16 Back to list

Characteristics and classification of automobile sealing strips

The automobile sealing strip has the function of filling various gaps and gaps between the components of the vehicle body, and has the functions of shock absorption, water prevention, dust prevention, sound insulation, decoration, etc., to improve the comfort of the driving experience and protect the vehicle body.

Overview: General owners experience that their car is in a certain state of operation, such as high-speed driving, gravel roads, downtown areas, and feel strong noise, then the most likely problem is the sealing performance of the car body. There are many ways to solve the problem, and the sealing strip is one of the cost-effective solutions. The car sealing strip is generally configured at the time of delivery, and the quality is uneven, After a period of use, there will be premature aging, deterioration and disappearance of sealing performance. At this time, replacing a new sealing strip will greatly improve the noise in the car. Automobile sealing strip is a very useful product to solve the noise problem.

Classification:

Classified by the name of the installation part (component) of the sealing strip

The engine cover sealing strip can also be divided into front, side wall and rear; Door frame sealing strip; Front and rear windshield sealing strips; Side window sealing strip; Sunroof sealing strip; Sealing strip of door header; Window guide channel sealing strip; Inner and outer side strips; Trunk sealing strip; Anti-noise sealing strip; Dust strips, etc.

Classification by section shape:

It can be divided into solid core products (round, square, flat section shape), hollow products and metal rubber composite products. Among them, metal rubber composite sealing strip accounts for more than 60%. Section design is very important for rubber sealing strip. First of all, the shape and size of the sealing lip should be designed. The sealing lip on both sides should contact the glass from both sides of the window glass with the same and appropriate force. The length and thickness of the lip should be appropriate. Too thick or too long will make the glass lifting resistance too large, and too thin or too short will cause the glass not to be well guided and sealed, resulting in vibration, noise and rain leakage; The second is the design of the shape and size of the bottom of the section. There are bulges on the section of the window steel channel, which are used to assemble the guide channel. Therefore, the corresponding structure should be designed at the bottom of the guide channel section, which is not only easy to install, but also can use the elasticity of the sealing strip itself to attach to the steel guide channel to prevent it from falling out; Finally, the shape and size of the outer lap. In order to improve the appearance, the outer finish of the guide groove should be closely fitted with the vehicle body.

Classification according to sealing characteristics:

It can be divided into weather sealing strip and general sealing strip. Among them, the weather sealing strip has a hollow foam tube, which has a good temperature and humidity retention function. Common weather sealing strips include door frame sealing strip, trunk sealing strip, engine case cover strip, etc. Common sealing strips include front and rear windshield sealing strips, corner window sealing strips, inner and outer side strips, etc.

Classification according to compound structure of rubber:

It can be divided into pure rubber sealing strips - composed of a single rubber type; II. Composite sealing strip - composed of dense rubber and foam sponge rubber, often containing metal skeleton material in the axial direction inside the dense rubber; Three-composite sealing strip - composed of two kinds of dense adhesive (one of which is light color) and sponge adhesive, usually containing metal skeleton and reinforcing fiber inside the dense adhesive. Four composite sealing strips - Shanghai Shenya Seals Co., Ltd. has taken the lead in developing and producing composite sealing strips composed of four kinds of rubber materials in China. A thin protective layer of rubber is coated on the surface of the rubber (foam tube), thus further improving the service life of the seal.

Classification by material type:

It can be divided into rubber sealing strips; Plastic sealing strip; Thermoplastic elastomer sealing strip.

Classification by surface treatment status:

The surface of some sealing strips can be divided into flocking sealing strips after additional treatment; Surface coating sealing strip; Special function classification of sealing strip with fabric trim:

Some sealing strips have electronic intelligence functions, such as anti-pinch sealing strips.

characteristic:

In the low temperature resistance test at - 40 ℃, the sealant strip remained firm, not brittle, and remained soft and with good adhesion, showing excellent cold resistance. However, at 120 ℃, the weatherability of the sealing strip is still good, the elastic property is maintained, and the shape and function are not affected.

The selection of sealing material determines its permanent softness and elasticity. Through formula adjustment, the softness of the sealant after drying is improved to form a good sealing layer between the sheet metal and the rubber strip. The unique high elasticity of butyl rubber ensures that the sealant is easy to peel off from the metal sheet metal without polluting the sheet metal.

The automobile sealing strip is mainly made of EPDM rubber with good elasticity and compression deformation resistance, aging resistance, ozone, chemical action, wide use temperature range (- 40 ℃~+120 ℃), which is foamed and tightly compounded. It contains a unique metal clamp and tongue-shaped buckle, which is durable and easy to install.

Mar . 15, 2023 19:07 Back to list

Characteristics and classification of automobile sealing strips

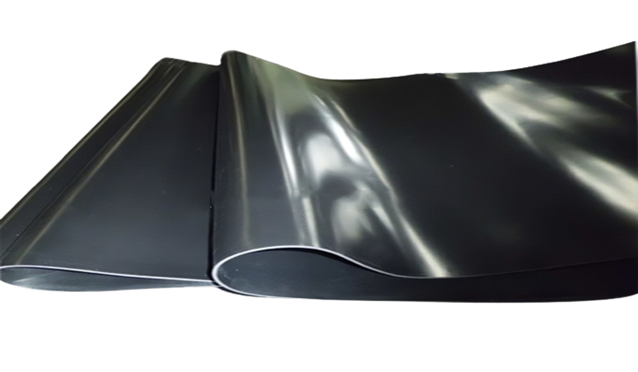

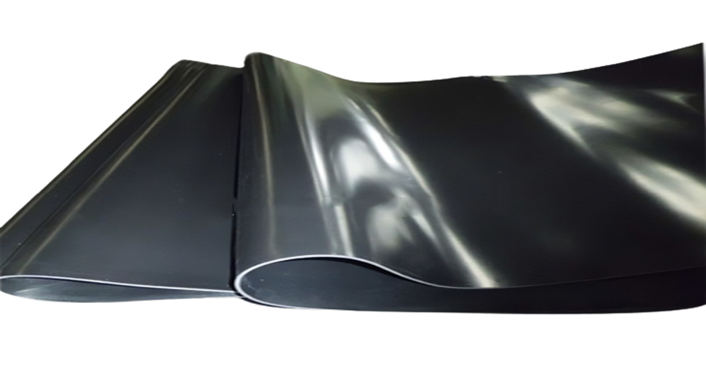

The rubber plate has high hardness. It is a sheet product with a certain thickness and a large area, which is made of rubber as the main material (including fabric, metal sheet and other reinforcing materials) and vulcanized. It is called rubber plate for short. In recent years, with the rapid development of the construction industry and the continuous improvement of people's living standards, rubber products show its strong vitality. For example, in the construction industry, at present, most buildings use cement prefabricated slabs. For example, laying rubber slabs on the floor can reduce the noise and improve the floor life. The rubber plate can also produce various density rubber window strips, which can effectively eliminate the problem of air and rain leakage. With the development and change of production and living needs, rubber sheets can be produced in black, gray, green, blue and other colors to meet the needs of different enterprises and life.

In the industrial industry, rubber plate is mainly used for corrosion prevention, wear resistance, impact resistance and protection of equipment and devices used. In the mining industry, the rubber plate is mainly wear-resistant and impact-resistant to protect its equipment and related pipeline equipment, which can extend the service life of its equipment. In the cultural education system, it is generally used for printing and plate-making. With the innovative development of social science and technology, rubber sheet, as a new scientific and technological synthetic material, has been selected by more and more industries, with a wide range of applications and uses. This material plays a special role in industrial and mining enterprises, transportation departments and building floors. In our daily life, we are exposed to sealing rubber rings, rubber mats, door and window seals, and the laying of workbenches and floors.

In industrial occupations, rubber sheets are mainly used for corrosion prevention, wear resistance, impact resistance and maintenance of equipment and equipment used. In the mining industry, the rubber plate is mainly wear-resistant and impact-resistant to maintain its equipment and related pipeline equipment, which can extend the service life of its equipment. In the cultural education system, it is generally used for printing and plate-making. With the innovative development of social science and technology, rubber sheet, as a new scientific and technological composition material, has been selected by more and more professions, and has a wide range of applications and uses. This material plays a special role in industrial and mining enterprises, transportation departments, and buildings and buildings. In our daily life, we come into contact with sealing rubber rings, rubber mats, door and window seals, and laying work benches and floors. Of course, with the continuous development of skills, the use and function of rubber plate will be more and more extensive in the future, and rubber plate will also have more and more advantages.

EPDM rubber sheets are mainly used in power distribution rooms and power distribution stations. They are used for laying the ground of power distribution equipment and play a role of insulation. Due to the high humidity in the dry season, the insulation protection work becomes more important. Due to the large amount of rain in the dry season, many power distribution rooms and power distribution rooms have started to use insulation rubber mats of higher standards for safety, so the demand for products has increased a lot.

Features of EPDM rubber plate:

EPDM rubber sheet has high tear resistance, good oil resistance, high temperature resistance, corrosion resistance, aging resistance, and strong elasticity; Purpose: It can be used to work in oil medium in low and high temperature environment. It can punch oil seals, gaskets and seals. It has good sealing performance and is suitable for environment with high corrosion resistance requirements; The features are green and environmental protection. The drum vulcanizer produces jointless, one-time molding, pollution-free, wear-resistant, corrosion-resistant, high and low temperature resistant.

EPDM rubber sheet insulating rubber pad composition: The insulating rubber pad is mainly made of rubber insulating materials, and is made of non-polar rubber with excellent insulating properties such as NR, SBR and IIR. Characteristics of insulating rubber mat: harmless irregularity refers to the appearance irregularity formed during production. The insulating rubber pad with good quality has no peculiar smell, no bubbles, no pits, and its appearance is smooth, neat and clean. Thickness measurement of insulating rubber pad: more than 5 different points shall be randomly selected on the entire insulating pad for thickness measurement and inspection. Micrometer or instrument with the same accuracy can be used for measurement. The accuracy of the micrometer shall be within 0.02mm, the diameter of the measuring drill shall be 6mm, the diameter of the flat presser foot shall be (3.17 ± 0.25) mm, and the presser foot shall be able to exert (0.83 ± 0.03) N pressure. The insulating mat shall be placed flat to make the micrometer measurement smooth.