Oct . 21, 2024 17:00 Back to list

china other sealing strips

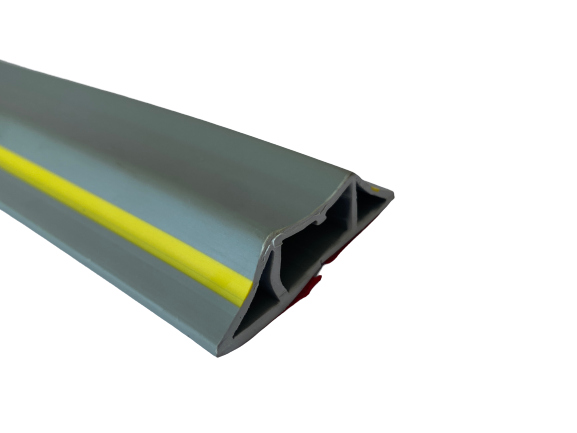

The Importance of Quality Sealing Strips in Various Applications

Sealing strips are often overlooked components in both industrial and residential settings, yet they play a crucial role in ensuring efficient operations and comfort. Particularly in China, where manufacturing practices are continually evolving, the demand for high-quality sealing strips is on the rise. This article explores the significance of these materials across different applications.

1. Applications in Construction

In the construction industry, sealing strips are primarily used for windows and doors to prevent air and water infiltration. A well-installed sealing strip not only enhances energy efficiency by insulating buildings but also significantly improves occupant comfort. This is particularly important in regions of China that experience extreme seasonal temperatures. With the rise of environmentally conscious construction practices, sealing strips have become essential in meeting stringent energy regulations.

2. Use in Automotive Industry

The automotive industry is another sector that heavily relies on sealing strips. These components are vital for ensuring that vehicles are airtight, which is crucial for reducing noise, ensuring passenger comfort, and enhancing fuel efficiency. Quality sealing strips can also protect against environmental elements, thus lengthening a vehicle's lifespan. As the automotive industry in China continues to grow, the necessity for dependable sealing components is more pronounced than ever.

china other sealing strips

In various industrial applications, sealing strips serve to protect machinery and electronic components from dust, moisture, and other contaminants. Industries such as electronics, manufacturing, and food production require precision sealing to maintain product quality and safety. The rise of automation and technology in Chinese manufacturing processes necessitates high-performance sealing solutions that can withstand demanding environments.

4. Importance of Material Quality

The material used in sealing strips is crucial for their effectiveness. Common materials include rubber, silicone, and PVC, each offering unique benefits and drawbacks. For example, rubber seals can provide excellent elasticity and resistance to wear, while silicone strips offer superior temperature resilience. In the competitive manufacturing landscape of China, the choice of material directly affects the performance and longevity of sealing strips, thus influencing overall product quality.

5. Custom Solutions for Diverse Needs

As industries diversify, there is a growing demand for custom sealing solutions tailored to specific application needs. Chinese manufacturers are increasingly adopting advanced technologies and materials science to develop sealing strips that meet unique specifications. Whether it's for high-temp applications in factories or specific energy-efficient designs for construction, customization is key to meeting the specific demands of different sectors.

Conclusion

The importance of sealing strips cannot be understated, as they contribute to operational efficiency, energy conservation, and product longevity across various sectors. In China’s rapidly growing economy, the emphasis on quality and innovation in sealing strip manufacturing will continue to be a significant factor in industrial advancements. Understanding the diverse applications and evolving trends in sealing technology is essential for businesses aiming for sustainability and efficiency in their operations. As the market grows, so does the potential for innovation in this crucial component.