Nov . 12, 2024 04:41 Back to list

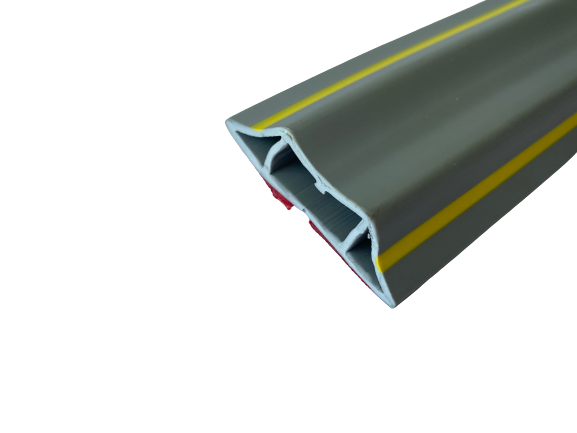

epdm automotive fuel tank gasket manufacturer

The Importance of EPDM Automotive Fuel Tank Gaskets

In the automotive industry, every component plays a crucial role in ensuring the efficiency and safety of vehicles. Among these components, the gasket is often overlooked, yet it is vital for the optimal performance of fuel tanks. EPDM (Ethylene Propylene Diene Monomer) automotive fuel tank gaskets have gained significant popularity due to their superior properties and reliability. This article delves into the significance of EPDM gaskets, their manufacturing process, and the benefits they bring to automotive applications.

Understanding EPDM

EPDM is a type of synthetic rubber known for its excellent weather resistance, durability, and flexibility. It is particularly resistant to extreme temperatures, UV radiation, ozone, and various chemicals, making it an ideal material for automotive applications. The unique properties of EPDM allow it to maintain its integrity over time, even when exposed to fuels, oils, and other substances commonly found in automotive environments.

The Role of Gaskets in Fuel Tanks

Fuel tank gaskets serve as seals that prevent leaks and ensure that fuel is contained within the tank. A leak not only poses a safety hazard but can also lead to environmental contamination and fuel loss. Therefore, choosing the right gasket material is critical. EPDM gaskets offer excellent sealing capabilities, protecting against fuel leaks and ensuring that the fuel tank operates efficiently.

Manufacturing Process of EPDM Gaskets

The process of manufacturing EPDM gaskets involves several steps to ensure precise dimensions and quality. First, the EPDM rubber is formulated with various additives to enhance its properties. This mixture is then molded into the desired shape using high-precision machinery. The molding process can be done through techniques such as compression molding, transfer molding, or injection molding, depending on the specific requirements and design of the gasket.

Once molded, the gaskets undergo rigorous quality control tests to ensure they meet industry standards. These tests can include thermal cycling, chemical resistance, and physical property evaluations. Only those gaskets that pass these tests are approved for use in automotive applications, ensuring high reliability and performance.

epdm automotive fuel tank gasket manufacturer

Advantages of EPDM Fuel Tank Gaskets

1. Durability EPDM gaskets are known for their long life span, resisting wear and degradation over time. This durability reduces the frequency of replacements, saving manufacturers and consumers time and money.

2. Chemical Resistance EPDM's resistance to various chemicals ensures that the gaskets can withstand exposure to fuels and oils without breaking down. This resistance is crucial for maintaining the integrity of the fuel tank.

3. Temperature Extremes EPDM gaskets can endure extreme temperature variations, making them suitable for use in diverse climates. This adaptability is essential for global automotive markets where vehicles operate in different environmental conditions.

4. Eco-Friendly As the automotive industry moves towards more sustainable practices, EPDM rubber is seen as an eco-friendly option. Its long life and recyclability contribute to lower environmental impact.

5. Cost-Effectiveness While the initial cost of EPDM gaskets may be higher than other materials, their durability and performance lead to lower overall expenses. Fewer replacements and maintenance needs translate to significant savings in the long run.

Conclusion

In conclusion, EPDM automotive fuel tank gaskets are an essential component in the manufacturing of reliable vehicles. Their exceptional durability, chemical resistance, and adaptability to varying temperatures make them a top choice for manufacturers. As the automotive industry continues to evolve, the importance of high-quality materials like EPDM will only grow. By investing in EPDM gaskets, manufacturers can ensure that they deliver safe, efficient, and environmentally friendly vehicles to consumers worldwide.