Aug . 06, 2024 14:48 Back to list

Exploring Manufacturers of Automotive Fuel Tank Gaskets for Efficient Fuel System Solutions

Understanding Car Fuel Tank Gasket Factories and Their Importance

In the automotive industry, various components play a pivotal role in ensuring the efficient functioning of vehicles. One such component is the fuel tank gasket. These gaskets are crucial for maintaining the integrity of the fuel system, preventing leaks, and ensuring that the vehicle runs efficiently. The production of these gaskets takes place in specialized factories that focus on high-quality manufacturing processes, strict quality control, and adherence to industry standards.

The Role of Fuel Tank Gaskets

A fuel tank gasket serves as a seal between the fuel tank and its associated components, such as the fuel pump and sending unit. Its primary function is to prevent fuel leaks, which can be hazardous and lead to various issues, including reduced fuel efficiency, engine performance problems, and environmental hazards. Given the importance of safety and reliability in automotive applications, the quality of the gasket is paramount.

Warehousing and Supply Chain Management

Car fuel tank gasket factories play a critical role in the supply chain of automotive manufacturing. They work closely with automotive manufacturers, aftermarket suppliers, and distributors to ensure timely delivery of high-quality gaskets. Efficient inventory management systems are crucial to ensure that production lines are not halted due to a lack of parts. Factories often utilize advanced logistics solutions to streamline this process, ensuring that they can meet the demands of their customers effectively.

Manufacturing Processes

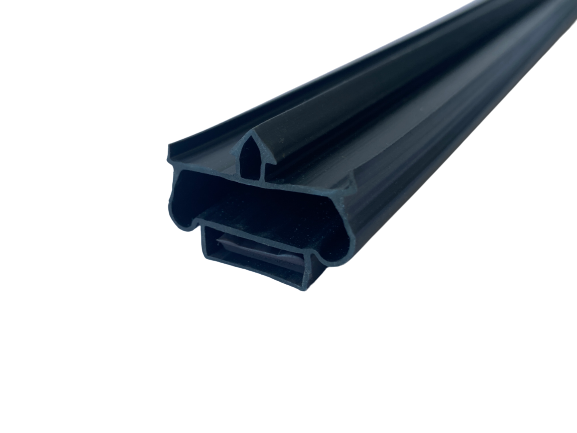

The manufacturing of fuel tank gaskets typically involves several key processes, including material selection, molding, curing, and quality assurance. Factories primarily use materials such as rubber, silicone, or specialized composites, which offer the necessary flexibility and durability required for automotive applications. The gaskets are typically molded into their final shape using processes such as compression molding or injection molding.

car fuel tank gasket factories

Once molded, the gaskets undergo curing, a process that enhances the material properties to withstand temperature variations and chemical exposure from fuels. After curing, the gaskets are subjected to rigorous quality control testing, including pressure tests and leak detection, to ensure they meet the specified industry standards.

Technological Innovations

In recent years, there has been a significant shift towards automation and advanced manufacturing technologies in gasket factories. These innovations enhance precision and reduce production times while maintaining high quality. For instance, computer numerical control (CNC) machines can produce gaskets to exact specifications, minimizing waste and improving efficiency. Additionally, the application of advanced materials science has led to the development of gaskets with improved heat and chemical resistance, which is vital in modern engines that operate under more demanding conditions.

Environmental Considerations

Car fuel tank gasket factories are increasingly becoming aware of their environmental impact. Many are adopting sustainable practices, such as reducing waste, recycling scrap materials, and utilizing eco-friendly manufacturing processes. As governments and consumers push for greener solutions in the automotive sector, these factories are adapting to meet the demands for sustainability while still delivering high-performance products.

Conclusion

Car fuel tank gaskets may seem like a small component in the vast machinery of automotive manufacturing, but their importance cannot be overstated. The factories that produce these gaskets are critical to the automotive supply chain, ensuring that vehicles operate safely and efficiently. With continuous advancements in technology and a growing emphasis on sustainability, the future of car fuel tank gasket manufacturing looks promising. As the industry evolves, these factories will play a vital role in the ongoing innovation and improvement of automotive components, ultimately benefiting consumers and the environment alike.